परिवर्तनं शक्तिः सृष्टेः आधारः

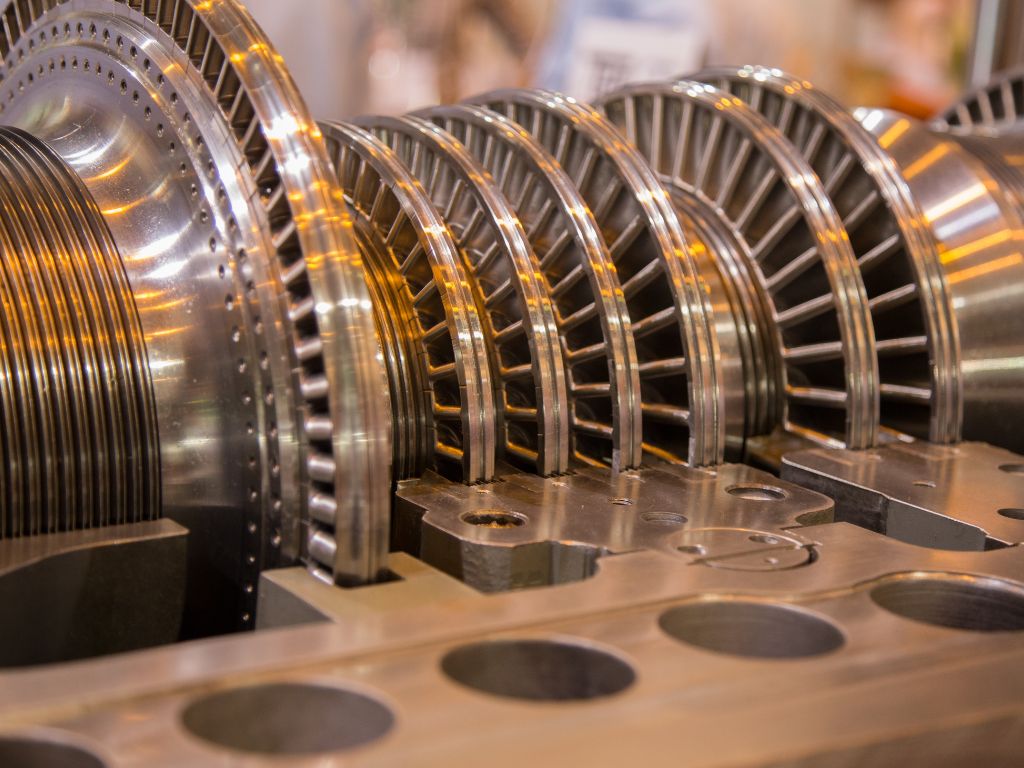

We are Engineering the Future of Processing

From cutting-edge spice processing solutions to high-efficiency spice plants, we engineer precision for seamless processing.

Our Expertise

Precision Engineering, Uncompromised Quality

MillNest brings specialised solutions across all critical stages of industrial processing that boost throughput, consistency, and energy efficiency—driving safe, high-quality solutions ready for scalable growth.

Coarse to Ultra-Fine Size Reduction

Precision grinding systems tailored for homogenous particle sizing...

Coarse to Ultra-Fine Size Reduction

Precision grinding systems tailored for homogenous particle sizing, ensuring dust-free environment and less wastage.

Drying, Mixing & Blending

High-performance systems ensure uniform drying, mixing and blending, preserving...

Drying, Mixing & Blending

High-performance systems ensure uniform drying, mixing and blending, preserving the product's natural qualities for reliable output.

Steam Sterilization & Pasteurization

HT-ST natural steam treatment for contamination-free ingredients...

Steam Sterilization & Pasteurization

HT-ST natural steam treatment for contamination-free ingredients, safeguarding quality in heat-sensitive powders, granules and whole products.

Process Solutions & Engineering

End-to-end solutions for optimized production flow, energy use, and yield,...

Process Solutions & Engineering

End-to-end solutions for optimized production flow, energy use, and yield, with accessible spare and raw material management for improved quality.

On-Site Service & Maintenance

Proactive support for peak system performance, covering maintenance, retrofitting...

On-Site Service & Maintenance

Proactive support for peak system performance, covering maintenance, retrofitting, upgrades, and on-site installation, supervision, training and commissioning.

Innovation Rooted in Purpose,

Driven by Research

At MillNest, our R&D philosophy is simple yet powerful: We transform raw elements into solutions that empower industries, nourish communities, and sustain vital resources. Through rigorous research and a commitment to sustainable impact, we develop solutions built for the future of industrial processing.

Innovative Spice Processing Technologies

Unlocking Precision, Efficiency, and Scalability

Our Process Solutions enable you to achieve operational excellence, scaling production with precision while meeting global standards for quality, compliance, and sustainability.

Pulverizing & Milling

Featuring robust hammer and classifier mills, our milling solutions for size reduction of solid and semi-solid particles

Granulation & Cutting

Our granulation solutions ensure exact particle sizing, reducing downtime and improving material consistency in demanding applications.

Mixing & Blending

Engineered for consistent dispersion and heat-sensitive handling, our mixers are designed for reliable performance in high-volume production.

Drying & Cooling

Our dryers and coolers provide uniform moisture control, preserving quality in heat-sensitive materials across large volumes.

Pasteurization & Sterilization

Our high-capacity autoclaves and screw-type systems ensure effective pasteurization and sterilization, meeting safety standards without compromising quality.

Bulk Conveying & Storage

From pneumatic conveying to durable silos, our systems ensure smooth, safe material flow and storage, reducing labor and maintaining product quality.

De-dusting & Filtration

Our filtration solutions capture airborne contaminants and harmful gases etc, protecting product integrity, equipment longevity, and air quality.

Waste Heat Recovery

Our high-performance heat exchangers reduce energy costs by capturing waste heat, lowering emissions, and enhancing sustainability.

Weighing & Batching

Automated systems ensure consistent, accurate material ratios, minimizing waste and enhancing production accuracy.

Precision Processing Equipment

Advanced Machinery for Enhanced Efficiency and Precision

High-speed milling for consistent particle sizes, adaptable to various materials and throughput requirements.

MillNest Universal Mill

(MUNI)

High-speed milling for consistent particle sizes, adaptable to various materials and throughput requirements.

High-speed milling for consistent particle sizes, adaptable to various materials and throughput requirements.

Precision cutting for tough materials, ensuring consistent particle size with minimal fines.

Service Portal

Comprehensive Support & Services for Seamless Operations

MillNest brings specialised solutions across all critical stages of industrial processing that boost throughput, consistency, and energy efficiency—driving safe, high-quality solutions ready for scalable growth.

Professional maintenance solutions to extend equipment life and optimize performance.

Expert installation and commissioning for a smooth start to production.

Customizable contract processing services to meet your unique production demands.

Our Clients

Industry Sectors

Tailored Solutions for Diverse Industry Sectors

Our processing solutions and equipment are engineered to meet the unique demands of various industries, ensuring precision, quality, and efficiency.

- Pharmaceuticals

- Food & Spices

- Cosmetics

- Paints

- Fertilizers

- Agriculture

Pharmaceuticals

High-precision milling and blending for active pharmaceutical ingredients, ensuring consistent particle size distribution and compliance with stringent quality control standards across drug manufacturing and excipient preparation.

Food & Spices

Advanced grinding, sterilization, and blending systems for spices and food ingredients, preserving essential qualities like flavour and aroma, while adhering to food safety regulations and maintaining high production throughput.

Cosmetics

Efficient processing of powders, emulsions, and creams, ensuring precise particle sizing and consistent blending for cosmetic formulations, while maintaining purity and product integrity in skincare and beauty products.

Paints

Specialized equipment for pigment grinding and size reduction, ensuring uniform colour distribution and high-quality texture in paints and coatings, with optimized production flow and reduced material waste.

Fertilisers

Custom solutions for the blending, drying, and grinding of organic and inorganic fertilizers, are designed to enhance product uniformity and improve the efficiency of large-scale fertilizer production.

Agriculture

Integrated systems for the sorting, cleaning, and grinding of grains, millets, and pulses, delivering high yield, consistency, and efficiency for large-scale food processing operations.