Overview

Waste heat recovery is a pivotal step in enhancing energy efficiency across industries such as chemicals, food processing, and power generation. At MillNest, we specialize in advanced Waste Heat Recovery Systems featuring Shell Type Heat Exchangers and Fin & Tube Type Heat Exchangers. These systems are designed to capture and repurpose residual heat from industrial processes, reducing energy consumption, operational costs, and carbon footprints.

Our waste heat recovery solutions enable the generation of steam, hot water, or electricity from unused heat, providing industries with a sustainable energy source. Designed for efficiency and reliability, MillNest systems can improve overall process efficiency by up to 10%, with a fast payback period that enhances long-term cost savings.

Key Features

Optimized Efficiency

Improves overall system energy efficiency by up to 10%.

Versatile Applications

Handles high-temperature processes across various industries.

Robust Design

Durable construction for continuous operation under extreme conditions.

Quick ROI

Fast payback period, typically under two years

Customizable Solutions

Tailored configurations to meet unique industrial needs.

Equipment Overview

Case Studies

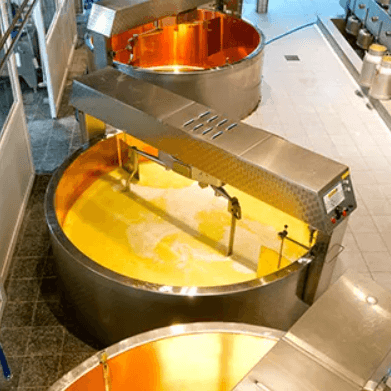

- Heat Recovery for a Food Processing Facility

- Enhancing Efficiency in a Dehydrated Onion Sterilization Plant

Results

- Reduced energy consumption by 12%.

- Lowered dependence on external energy sources.

- Automated operations minimized maintenance costs.

Results

- Improved Overall System Efficiency: Boosted process efficiency by 10%.

- Reduced Fuel Consumption: Lowered operational costs and fuel usage.

- Quick ROI: Achieved a payback period of just 18 months.

Why Choose MillNest Waste Heat Recovery Solutions?

Delivers consistent energy savings with quick ROI.

Supports environmental compliance and emission reduction goals.

Comprehensive consultation, installation, and maintenance.

Customized for seamless integration with existing processes.