In today’s global spice market, spice plants face immense pressure to deliver quality. Whether it’s turmeric, chili, coriander, or custom blends, customers expect a consistent grind, safe processing, and export-compliant hygiene. According to the World Health Organization, unsafe food causes millions of illnesses annually, underscoring the critical importance of stringent processing controls. Behind this consistency is more than just raw power—it’s precision, planning, and processing reliability.

That’s exactly what MillNest delivers through its advanced spice grinding systems. MillNest’s next‑generation line MillNest Hammer Mill (MHAM) and the MillNest Air Classifying Mill (MACM) give processors the accuracy, throughput, and reliability demanded by premium brands and exporters.

Let’s explore why your spice plant needs MillNest—and why we’re more than just an equipment supplier.

Spice Grinding Has Evolved. Have You?

The Cost of Standing Still :

As spice grinding technology advances, sticking to outdated processes comes at a steep operational cost. Here’s what legacy issues mean for modern spice producers:

| Legacy Issue | Impact on Spice Producers |

| Variable particle size | Brand inconsistencies and customer complaints |

| Heat build-up during milling | Loss of essential oils and diminished flavor profile |

| High wear and unscheduled outages | Expensive downtime, missed orders, and increased maintenance costs |

| Limited hygiene controls | Risk of export rejection due to non-compliance |

In short, legacy setups fail where modern spice plants need to scale, comply, and compete.

MillNest solves each of these pain points with an integrated two‑stage architecture built around MAHM and MACM, specifically engineered to handle complex spices like turmeric, chili, pepper, and blended masalas—without compromising quality.

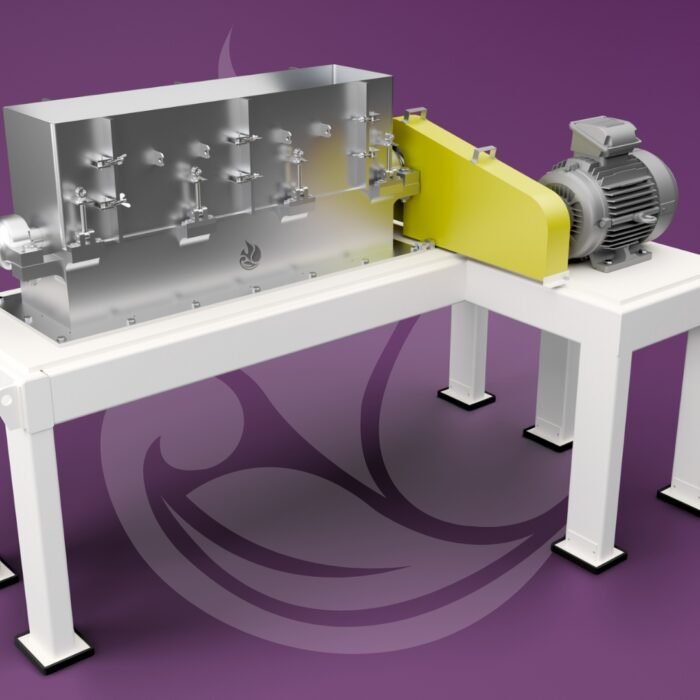

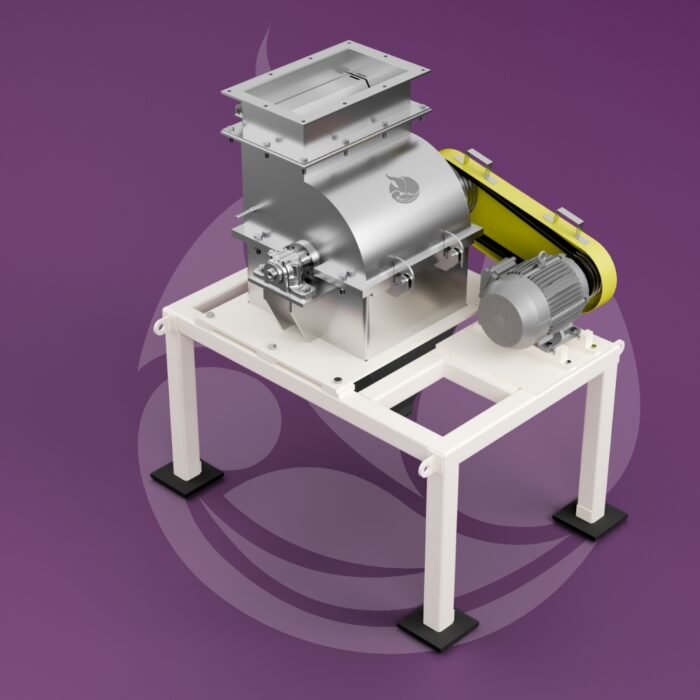

MHAM: High-Impact Primary Grinding

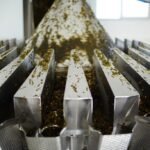

The MillNest Hammer Mill (MHAM) is a high-efficiency impact pulverizer, capable of handling everything from whole turmeric roots, dried chilies, coriander seeds, peppercorns, and more. It grinds materials into particle sizes ranging from 500 microns to 3 mm, making it perfect for coarse and medium grinding stages.

Why it matters:

- High-speed rotating hammers deliver uniform size reduction.

- An integrated perforated screen ensures that only properly sized material passes through.

- Positive suction flow keeps operations clean and dust-free—an essential for spice plants.

Key Advantages:

- Industrial-scale throughput: 100–5000 kg/hr

- Energy-efficient: Minimal power usage per kg of output

- Durable and low maintenance: Modular build, stainless steel construction

- Customizable output: Easily adjust hammer types and screen sizes

Best Use Case:

Perfect for grinding raw turmeric, chili, or spices into granules, which can then be finely processed using a classifier mill.

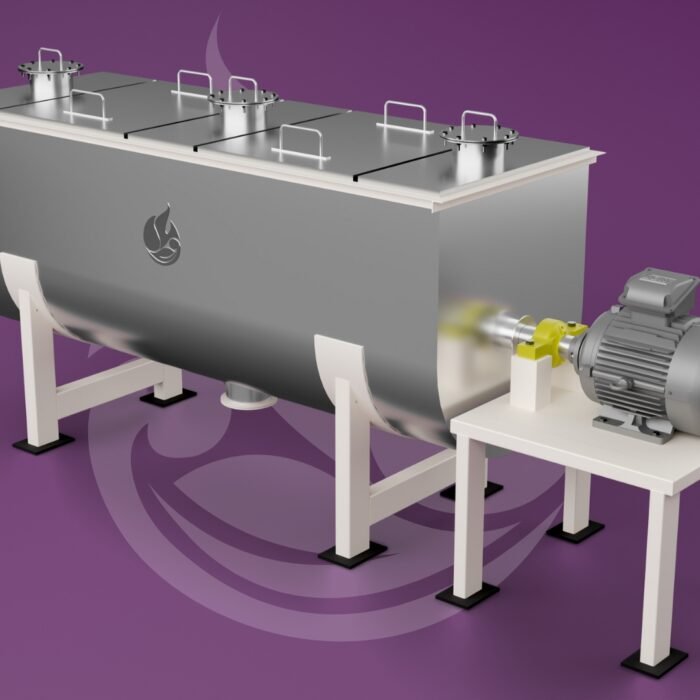

MACM: Precision at a Micron Level

Where MHAM powers through raw input, the MillNest Air Classifying Mill (MACM) delivers precision. It’s a dual-function machine that combines impact grinding and air classification, allowing you to produce fine, uniform spice powders with minimal heat generation.

This is critical in spice processing, where overgrinding destroys essential oils and modifies key chemical composition of the ingredients – especially in turmeric and chili.

Key Benefits:

- Dynamic classifier wheel guarantees tight cut‑points without over‑grinding.

- Single‑pass design slashes recirculation energy.

- Compact footprint fits retrofit projects as well as green‑field builds.

- Scalable capacity: From 100 to 4000 kg/hr

Applications:

- Chili powder

- Turmeric powder

- Cumin, pepper, or multi-spice blends

- Fine flour and sugar powder

With the MACM, your spice plant gains the ability to produce export-quality products consistently—batch after batch.

Beyond Equipment: MillNest as Your Turnkey EPC Partner

Buying equipment is one thing. Building a world-class processing plant is another.

Choosing MillNest means partnering with a full‑service EPC team that has delivered 30+ turnkey spice plants, offering:

- Process & layout engineering – airflow, dust control, HVAC.

- Utility integration – electricals, compressed air, cleaning‑in‑place.

- Installation & commissioning – mechanical alignment, FAT/SAT, operator training.

- Regulatory readiness – HACCP, FSSAI, US FDA, EU 1935/2004.

Whether you’re scaling from 2 to 8 TPD or modernising a brown‑field site, we blueprint, build, and balance the entire line around your product mix and commercial targets.

This is why food processors, spice exporters, and private label brands trust us—not just for equipment, but for performance they can scale with.

Spares & Lifecycle Maintenance – Uptime Engineered In

Even the best machines need care. With MillNest, support doesn’t stop at commissioning.

That’s why MillNest offers a robust lifecycle support system, including:

- OEM‑calibrated spares – hammers, classifier wheels, liners, rotors—stocked locally for < 48 hr dispatch.

- Predictive AMCs – vibration analytics + oil‑analysis to spot failures before they occur.

- Retrofit kits – upgrade legacy hammer mills to MAHM spec without civil changes.

- Rapid‑response field teams – book via our web portal or WhatsApp for same‑day remote triage.

In the absence of a digital catalog, customers can easily get in touch via our website to request spares, send enquiries, and get expert advice.

Our WhatsApp chat support ensures real-time responses—because every minute of downtime costs you more than just production.

Engineering for Tomorrow’s Demands

From screw feeder to silo discharge, every MillNest solution is engineered for one thing—performance.

What sets MillNest apart isn’t just our product specification sheet—it’s our thinking:

- Our MACM’s classifier settings minimize fines in chili powder.

- Reduced oil loss: MAHM and MACM keep turmeric curcumin and chili capsaicinoids intact.

- Our spares are stress-tested for durability and a perfect fit—ideal for replacing legacy parts prone to failure.

This mindset—engineering for uptime and output—is what makes MillNest more than a vendor. We’re your processing partner.

Conclusion: Build the Spice Plants of the Future—Today

In a market where efficiency, safety, and consistency define success, you can’t afford a processing plant built on yesterday’s logic.

With MillNest’s MHAM and MACM at the core, your plant is equipped to:

- Handle coarse and fine spices with precision

- Scale operations without scaling downtime

- Meet domestic and export quality demands

- Operate with long-term cost efficiency

So whether you’re launching a new spice plant or upgrading your existing line, now is the time to go beyond machines—and invest in a partner who supports you at every step.

Let’s build your next spice line—engineered for uptime.