If you’re in the spice processing business, you already know the challenge: maintaining absolute consistency across thousands of batches while scaling production, controlling costs, and meeting increasingly stringent quality standards. It’s a balancing act that keeps many processors awake at night.

This challenge is familiar across spice manufacturers throughout India. The difference between thriving businesses and struggling ones often comes down to one critical factor: precision in recipe execution. And that’s exactly where automated recipe management systems are changing the game.

The Real Cost of Manual Processing

Consider a scenario that might sound familiar. A mid-sized spice processor was producing their signature garam masala blend—twelve different spices, each requiring precise proportioning. Their experienced operator had been doing this for years, measuring ingredients by hand, adjusting by feel and experience.

The product was good. But here’s what they discovered when operations were analyzed: batch-to-batch variation was running at 8-12%. Some batches were slightly too pungent, others a bit mild. Their retail customers were beginning to notice. Worse, they were losing 7% of raw materials to spillage, over-filling, and processing waste. For premium spices, that’s a significant hit to margins.

This isn’t an isolated case. It’s the reality of manual spice processing, no matter how skilled the operators are.

What Recipe Management Systems Actually Do

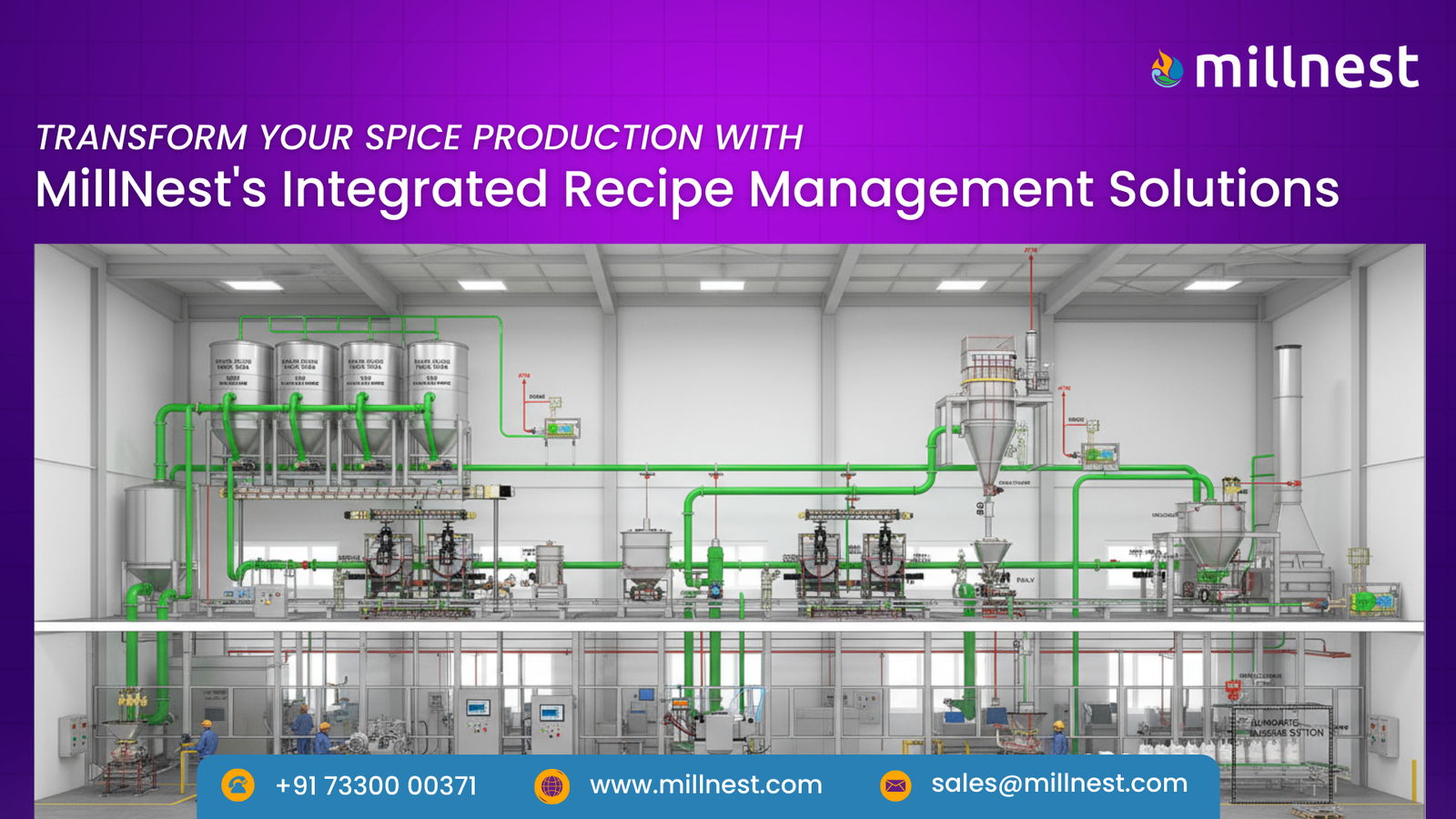

At MillNest, recipe management is approached as more than just automation—it’s about creating a digital nervous system for your entire spice processing operation. Think of it as having a master chef who never gets tired, never makes measurement errors, and executes every recipe with pharmaceutical precision.

Here’s how it works in practice: When a recipe is programmed into the system—let’s say your turmeric powder blend—it’s not just storing ingredient lists. The complete manufacturing intelligence is encoded: exact quantities down to the gram, grinding temperatures (maintained at 30-35°C for Low Temperature Grinding), blending speeds and durations, sifting parameters, even the timing for oleoresin additions when creating premium blends.

Once programmed, the system executes this recipe identically every single time. The SCADA (Supervisory Control and Data Acquisition) interface monitors every parameter in real-time, while PLC (Programmable Logic Controller) systems control the physical equipment. Operators interact through intuitive HMI (Human Machine Interface) touchscreens—selecting recipes, monitoring progress, and reviewing quality metrics.

The MillNest Difference: Integration Across Your Entire Process

What sets MillNest’s approach apart is integration. Many automation providers offer standalone solutions—a grinding mill here, a blender there. MillNest engineers complete ecosystems where recipe management orchestrates every stage:

Automated Ingredient Feeding: The system pulls exact quantities from ingredient silos based on your recipe. For mix spices requiring 8-15 different ingredients, this eliminates the measurement errors that plague manual batching. Whether producing a 100 kg batch or running at 2000 kg/hr, the precision remains constant.

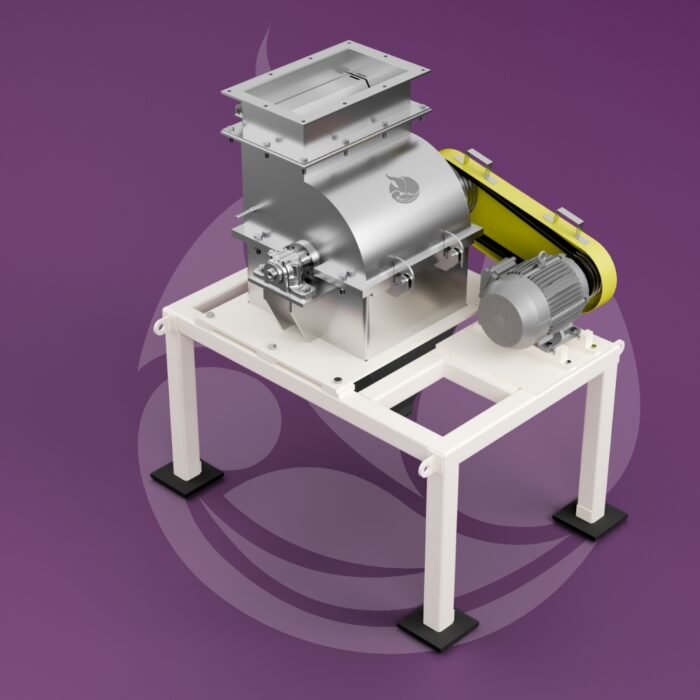

Temperature-Controlled Grinding: This is where recipe management becomes critical for quality. Different spices require different grinding approaches. MillNest’s Air Classifying Mill (MACM) and Hammer Mill (MHAM) systems integrate with recipe management to maintain optimal temperatures. For heat-sensitive spices, cryogenic grinding with liquid nitrogen is implemented, reducing volatile oil loss from 50-60% (in ambient grinding) down to just 15-20%. The system controls cryogenic injection rates automatically based on the specific spice being processed.

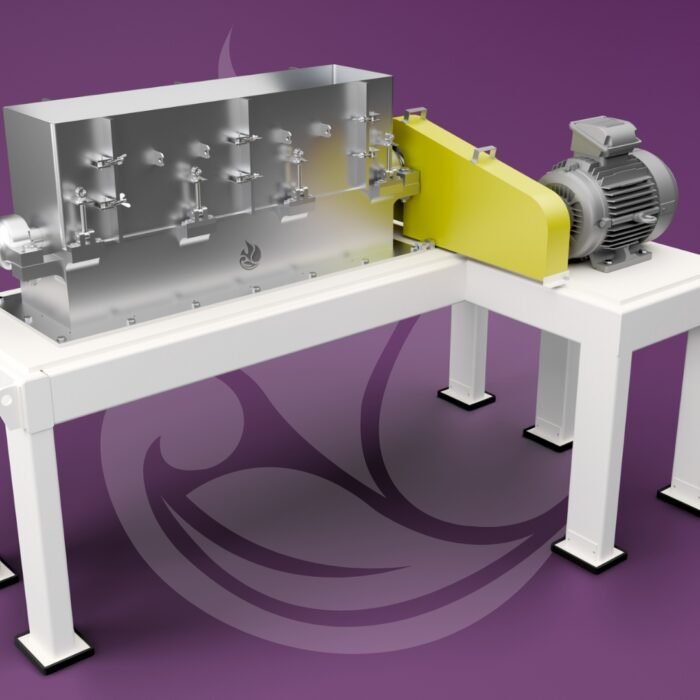

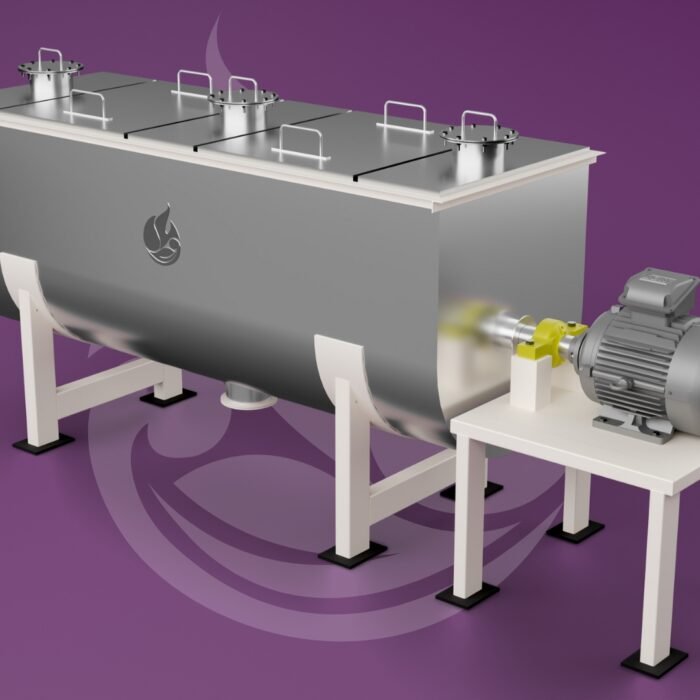

Precision Blending: MillNest’s Paddle Blender (MPBL) and Ribbon Blender (MRBL) systems don’t just mix—they execute calculated blending cycles specific to each recipe. A garam masala requires different mixing parameters than a curry powder. The system knows this and adjusts automatically, achieving 99% blend uniformity while preventing degradation of heat-sensitive ingredients.

Quality Integration: Metal detectors, Delumpers (MLUM), and sterilization systems (through the TEMA PROCESS partnership) are all coordinated by recipe management. If contamination is detected, the system diverts affected product without stopping the line. For export markets, sterilization parameters automatically adjust based on product characteristics, ensuring 5-log microbial reduction while preserving flavor compounds.

Three Paths to Implementation

Every processor has different needs and investment capacity. That’s why MillNest offers three automation levels:

Entry-Level (PLC with HMI): Perfect for transitioning from manual operations. Digital recipe storage, automated batching, and basic monitoring deliver immediate consistency improvements at accessible investment levels.

Advanced (SCADA with Field HMI): Mid to large operations benefit from real-time visualization, remote monitoring, automatic data logging, and predictive maintenance alerts. This level includes ERP integration for seamless production planning.

Complete Automation: The turnkey solution includes fully automated dispensing, zero manual measurement, automatic product changeover, CIP (Clean-In-Place) systems, and cloud connectivity for multi-site operations. This is the choice for export-focused processors and premium brands where consistency is non-negotiable.

The R&D Advantage: Test Before You Invest

One common concern: “How do we know this will work for our specific recipes?”

That’s precisely why MillNest built a comprehensive R&D facility in Pune. Before committing to production equipment, recipes can be tested on production-equivalent machinery. Grinding parameters are optimized for specific spice characteristics, different blending profiles are evaluated, cryogenic versus ambient grinding impact is assessed, and detailed data on throughput, particle size distribution, and quality metrics is provided.

This transparent trial capability eliminates the guesswork. Processors see exactly how their recipes perform at scale before making investment decisions.

Beyond Consistency: Strategic Business Benefits

While consistency is the obvious benefit, recipe management systems deliver strategic advantages that impact entire businesses:

Export Market Access: Complete digital traceability with batch records, ingredient documentation, and processing parameters satisfies the most stringent international compliance requirements. MillNest’s blockchain-enabled systems (available in advanced configurations) provide immutable records that export markets increasingly demand.

Faster Product Development: Testing new recipes becomes dramatically faster. Formulations can be iterated in the R&D facility, then scaled to production with confidence that results will be identical. This agility is crucial in responding to market trends.

Labor Optimization: Skilled staff shifts from routine batching tasks to quality control, process optimization, and new product development—higher-value activities that drive innovation.

Energy Efficiency: MillNest’s integrated approach optimizes energy use across the processing line. Typical installations achieve 15-20% energy savings through high-efficiency motors, heat recovery systems, and smart scheduling algorithms. Sustainability that impacts the bottom line.

Future-Proofing Your Operation

The spice industry is evolving rapidly. Consumer expectations for quality consistency, food safety regulations, and competitive pressures demand precision that manual processing simply cannot deliver reliably.

Recipe management systems aren’t emerging technology—they’re proven solutions that leading processors worldwide already depend on. The question isn’t whether to automate, but when and how.

MillNest’s modular approach allows phased implementation. Operations can start with critical bottlenecks—perhaps the grinding section—and expand automation as the business grows. Systems scale from 100 kg/hr operations up to 2000 kg/hr and beyond, adapting to new products, new markets, and new opportunities.

Your Next Step

For processors serious about scaling their spice processing business while maintaining quality, MillNest offers partnership beyond equipment supply—we engineer solutions that address specific challenges.

The MillNest team can conduct detailed operational audits, analyze production volumes and product mix, and design custom solutions that fit requirements and budgets. From initial trials in the Pune facility through installation, commissioning, and ongoing support, partnership continues for the long term.

The spice processors who are winning in today’s market aren’t the ones with the oldest traditions or the largest facilities. They’re the ones who’ve successfully married traditional spice craftsmanship with modern precision manufacturing. They’re the ones using recipe management systems to guarantee consistency while preserving the authentic flavors that define their brands.

That’s the MillNest difference. And it’s available to your business today.

Ready to explore how recipe management systems can transform your spice processing operation? Let’s connect.

MillNest – A Jaivik Food & Research Pvt. Ltd. Initiative