Introduction to Food Processing Automation

Food processing facilities face mounting pressure to increase throughput while maintaining stringent hygiene standards and reducing operational costs. Automated material handling systems in food processing plants have emerged as a critical infrastructure, enabling manufacturers to reduce manual handling, optimize workflows, and meet regulatory requirements.

This guide examines how automated material handling equipment transforms food processing operations, the technologies available, and practical frameworks for evaluating and implementing these systems.

What Are Automated Material Handling Systems?

Automated material handling systems encompass equipment, controls, and software that move, store, protect, and control materials throughout manufacturing without direct human intervention. In food processing environments, these systems handle raw ingredients, work-in-progress, and finished products while navigating unique challenges including sanitation requirements, temperature control, and regulatory compliance.

Core Benefits for Food Processing

Reduced Manual Handling: Automated systems eliminate repetitive lifting and carrying tasks, significantly reducing workplace injuries while redirecting labor toward higher-value activities like quality control and process optimization.

Enhanced Food Safety: Minimizing human contact with products reduces contamination risks. Stainless steel construction, clean-in-place capabilities, and enclosed transfer systems help processors meet FSMA, HACCP, and other regulatory standards.

Improved Traceability: Integrated tracking systems provide complete documentation of material movements from receiving through shipping, essential for recalls, audits, and quality investigations.

Processing Plant Efficiency: Automated conveyor systems operate continuously without breaks, maintaining consistent throughput that manual handling cannot match. This eliminates bottlenecks and enables production lines to run at optimal speeds.

Space Optimization: Vertical storage, compact conveyors, and optimized layouts maximize facility utilization, often eliminating the need for costly expansion while increasing capacity.

Product Quality Protection: Consistent, gentle handling reduces damage and waste. Climate-controlled systems maintain product integrity throughout the facility, particularly critical for fresh, refrigerated, and frozen foods.

Types of Material Handling Equipment for Food Processing

Conveyor Systems

Conveyor systems form the backbone of industrial material handling solutions in food facilities, moving products between processing stages efficiently.

Belt Conveyors: Versatile systems with food-grade belting materials that resist oils, moisture, and temperature extremes while meeting sanitation requirements.

Modular Plastic Belt Conveyors: Sanitary systems featuring interlocking plastic belts that resist bacterial growth, facilitate cleaning, and provide gentle handling for delicate items.

Roller Conveyors: Efficient for moving cases, cartons, and palletized products through packaging and distribution areas.

Spiral Conveyors: Space-efficient elevation systems that move products vertically within minimal horizontal space, ideal for multi-floor processing operations.

Chain Conveyors: Heavy-duty systems transporting bulk containers, totes, and pallets in washdown environments.

Pneumatic Conveying for Bulk Materials

Pneumatic systems transport dry bulk ingredients—flour, sugar, spices, powders—through enclosed pipes using air pressure or vacuum. This bulk material handling equipment prevents contamination, reduces dust, and enables flexible routing across multiple floors.

Automated Storage and Retrieval Systems (AS/RS)

AS/RS combines high-density storage with automated inventory management. Computer-controlled cranes or shuttles store and retrieve pallets or cases, maximizing vertical space while providing rapid inventory access.

Unit Load AS/RS: Handles full pallets in high-bay warehouses.

Mini-Load AS/RS: Manages cases, totes, or trays for batch processing and ingredient staging.

Robotic Palletizing

Industrial robots stack finished products onto pallets for shipping, handling diverse product sizes and stacking patterns while maintaining consistent quality.

Automated Guided Vehicles (AGVs) and Mobile Robots

Self-navigating vehicles transport materials throughout facilities without fixed infrastructure, offering flexibility for operations with variable production schedules or multiple production lines sharing storage areas.

MillNest's Material Handling Solutions for Food Processing

MillNest provides comprehensive material handling and conveying systems integrated with processing equipment to create complete production solutions for food processors.

Material Handling & Conveying

MillNest’s material handling systems ensure smooth, safe material flow throughout food processing facilities. Solutions include:

- Pneumatic Conveying Systems: Enclosed transport of powders and granular materials

- Screw Conveyors: Reliable bulk material transport for ingredients and finished products

- Bucket Elevators: Vertical material handling for multi-floor operations

- Belt and Chain Conveyors: Horizontal and inclined material transfer

- Dosing and Feeding Systems: Precise ingredient feeding integrated with processing equipment

These systems integrate seamlessly with MillNest’s processing equipment including hammer mills, blenders, and sterilization systems to create complete automated workflows.

Weighing and Batching Systems

Automated weighing and batching equipment ensures consistent, accurate material ratios while minimizing waste. MillNest’s solutions feature:

- Precise ingredient dosing systems

- Automated recipe management

- Integration with processing and packaging lines

- Real-time monitoring and data logging

Processing Equipment Integration

MillNest’s material handling solutions work in concert with their processing equipment portfolio:

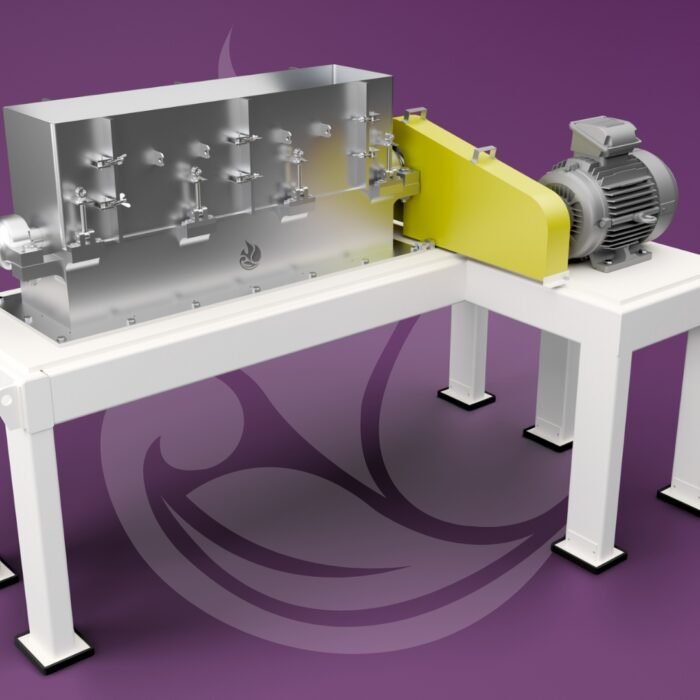

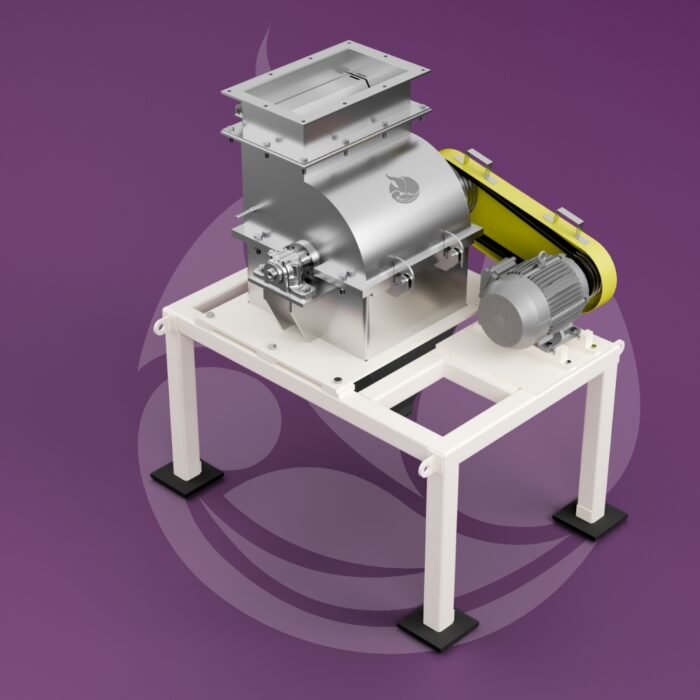

Size Reduction Equipment: MillNest Hammer Mills (MHAM), Universal Mills (MUNI), Cutter Mills (MCUT), and Delumpers (MLUM) process materials efficiently with integrated feeding and discharge conveyors.

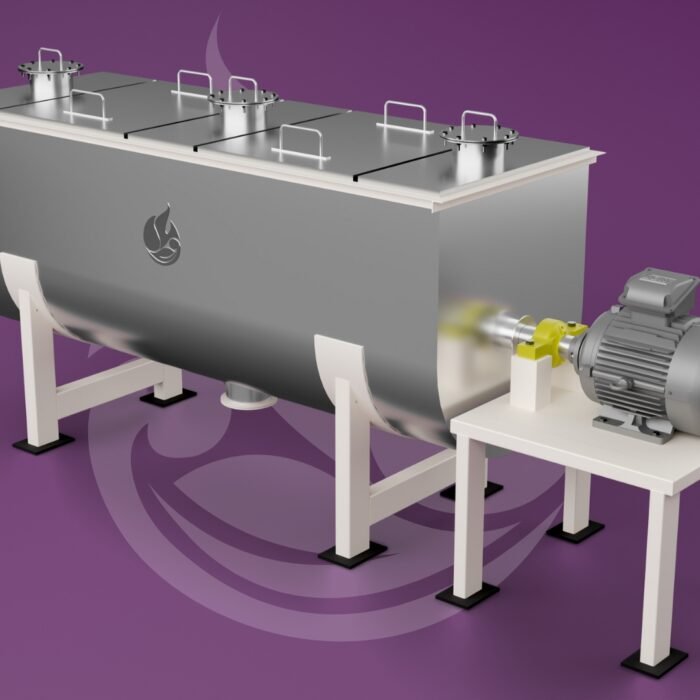

Mixing and Blending: MillNest Ribbon Blenders (MRBL) and Paddle Blenders (MPBL) provide uniform mixing with automated material feeding and discharge systems.

Sterilization Systems: Material handling integrates with pasteurization and sterilization equipment to maintain product safety throughout processing.

Key Considerations for Food Processing Applications

Sanitary Design Requirements

Material handling equipment must meet stringent hygiene standards:

- Stainless Steel Construction: 304 or 316 grade stainless resists corrosion and supports effective cleaning

- Washdown Capability: Equipment designed for regular cleaning without damage to components

- Minimized Horizontal Surfaces: Eliminating areas where residue or water might accumulate

- Proper Drainage: Sloped surfaces prevent water pooling

Temperature Control

Processing refrigerated or frozen products requires insulated conveyors and climate-controlled systems that maintain temperature while withstanding condensation and thermal cycling.

Integration with Existing Operations

New automation must interface with current equipment and facility infrastructure. Consider communication protocols, physical space constraints, utility requirements, and throughput matching with upstream and downstream processes.

Flexibility for Product Variety

Food processors frequently change production schedules and introduce new products. Systems should accommodate variety without extensive reconfiguration while supporting future capacity expansion.

Implementation Framework

Phase 1: Assessment

Document current material handling processes, identifying bottlenecks, inefficiencies, and safety concerns. Quantify handling frequency, distances, and labor hours for all material movements.

Define specific objectives, including throughput targets, space constraints, product characteristics, and integration requirements.

Phase 2: Technology Selection

Research suppliers with food processing experience and evaluate technologies against requirements. Develop detailed specifications covering performance, sanitary design, and control system interfaces.

Phase 3: Design and Engineering

Create detailed equipment layouts, optimizing material flow and accommodating future expansion. Design control system architecture and integration with existing platforms. Plan safety systems, including machine guarding and emergency procedures.

Phase 4: Installation and Commissioning

Establish clear schedules minimizing production disruption. Conduct factory acceptance testing before shipment and site acceptance testing under actual operating conditions.

Phase 5: Training and Optimization

Provide comprehensive operator and maintenance training. Develop standardized procedures and track performance metrics including uptime, throughput, and maintenance costs.

Evaluating Automation ROI

Cost Components

Consider capital investment (equipment, installation, facility modifications), operating costs (energy, maintenance, cleaning), and training expenses.

Benefit Quantification

Calculate labor savings from eliminated manual handling tasks. Quantify throughput improvements enabling increased production capacity. Estimate quality improvements from reduced damage and longer shelf life. Factor in space efficiency eliminating expansion needs and safety benefits reducing workers’ compensation costs.

Payback Analysis

Most automated material handling systems for food processing achieve payback within 2-5 years. Evaluate total cost of ownership over equipment life (10-20 years) rather than focusing solely on initial investment.

When to Automate

Strong Automation Candidates

Operations displaying these characteristics benefit most:

- High-volume, repetitive material movements

- Consistent patterns between fixed locations

- Heavy or awkward loads creating safety risks

- Long distances across facilities or between floors

- Processes requiring precise positioning or timing

- Operations in sanitary zones minimizing human presence

Manual Handling Situations

Certain operations may not justify automation:

- Infrequent movements with constantly changing patterns

- Extremely diverse products requiring frequent reconfiguration

- Temporary or seasonal operations

- Budget constraints or uncertain business conditions

Future Trends in Food Processing Automation

Artificial Intelligence: Advanced systems optimize routing, predict maintenance needs, and adapt to changing conditions through machine learning.

IoT Integration: Connected sensors provide real-time visibility into product location, equipment status, and environmental conditions enabling predictive maintenance and quality monitoring.

Collaborative Robotics: Next-generation robots work safely alongside humans without barriers, handling repetitive tasks while workers focus on complex decisions.

Sustainability Focus: Energy-efficient motors, regenerative braking, and optimized routing reduce environmental impact and operating costs.

Conclusion

Automated material handling systems represent strategic investments impacting every aspect of food processing operations. From improving food safety and product quality to optimizing labor and increasing throughput through reduced manual handling, properly designed systems deliver measurable returns.

Success requires careful evaluation of specific needs, thorough vendor selection, and ongoing optimization. Food processors who approach automation strategically consistently achieve their performance and financial targets while building more resilient operations.

MillNest provides integrated solutions combining material handling equipment, processing systems, and engineering expertise to help food processors achieve their automation goals. Contact our team to discuss how automated systems can transform your operations.