A Legacy of Innovation in Dry Powder Processing

MillNest has built its reputation as an industry leader in dry powder processing, delivering precision-engineered solutions that redefine efficiency and quality. With decades of experience in spice grinding, pneumatic conveyor systems, and size reduction technologies, the company has set new standards in industries ranging from food and pharmaceuticals to chemicals and nutraceuticals.

At its core, MillNest is committed to innovation. The ability to design and implement advanced turmeric powder processing systems, hammer mills, and autoclave sterilizers has positioned the company as a go-to partner for processing plants worldwide. But what truly sets MillNest apart is its comprehensive approach, one that integrates material handling, drying, sterilization, grinding, and quality control into a seamless, high-performance system.

Proven Success: Showcasing Our Achievements

MillNest has delivered numerous successful dry powder processing solutions across multiple industries. The company’s expertise has enabled manufacturers to optimize efficiency, reduce waste, and improve product quality, ensuring maximum yield from raw materials.

One of the standout case studies includes the efficient conveying of food powders in a spice processing plant. Before working with MillNest, the client struggled with material loss and uneven particle sizes in their spice grinder machines. By integrating pneumatic conveyor systems, MillNest eliminated manual handling inefficiencies, reduced contamination risks, and improved throughput. The result? A 25% increase in processing efficiency and significant cost savings in labor and raw material loss.

In the pharmaceutical sector, MillNest played a pivotal role in developing hygienic storage and sterilization solutions for powdered medications. Traditional sterilization methods often compromised product integrity, leading to inconsistencies in potency. By implementing autoclave sterilizers and ultra-clean storage systems, MillNest ensured precise microbial control while preserving active ingredients. This innovation not only met stringent pharmaceutical standards but also increased shelf life and product reliability.

Another example of MillNest’s expertise can be seen in its bulk handling solution for a leading chemical manufacturer. The client faced challenges in processing fine chemical powders due to electrostatic build-up and dust contamination. MillNest introduced a customized bulk handling system, integrating automated weighing, pneumatic conveying, and controlled atmosphere processing, which enhanced safety, minimized material loss, and streamlined production.

These case studies illustrate MillNest’s ability to solve complex industry challenges with tailored solutions, reinforcing its position as a market leader in dry powder processing.

Comprehensive Capabilities in Dry Powder Processing

MillNest offers an extensive portfolio of processing solutions, engineered to optimize performance across multiple applications. The company’s expertise extends across material handling, size reduction, drying, sterilization, and quality assurance, ensuring end-to-end efficiency for manufacturing plants.

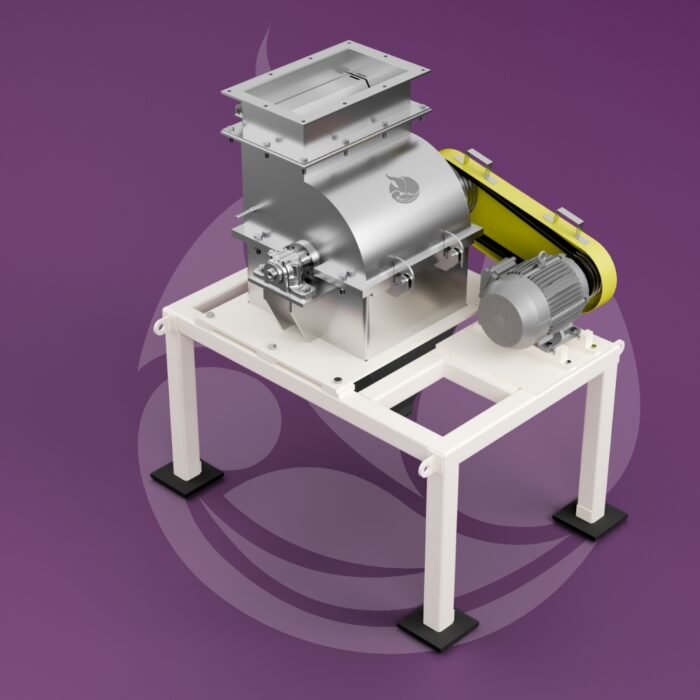

Material Handling & Pneumatic Conveying

In dry powder processing, precise material movement is critical. Manual handling can lead to product contamination, inconsistent batch quality, and increased processing time. MillNest’s pneumatic conveyor systems provide a seamless solution, enabling manufacturers to transport powders efficiently while maintaining purity and flow consistency. These systems are designed to handle delicate spice powders, pharmaceutical formulations, and chemical compounds with precision, ensuring minimal product loss and enhanced hygiene.

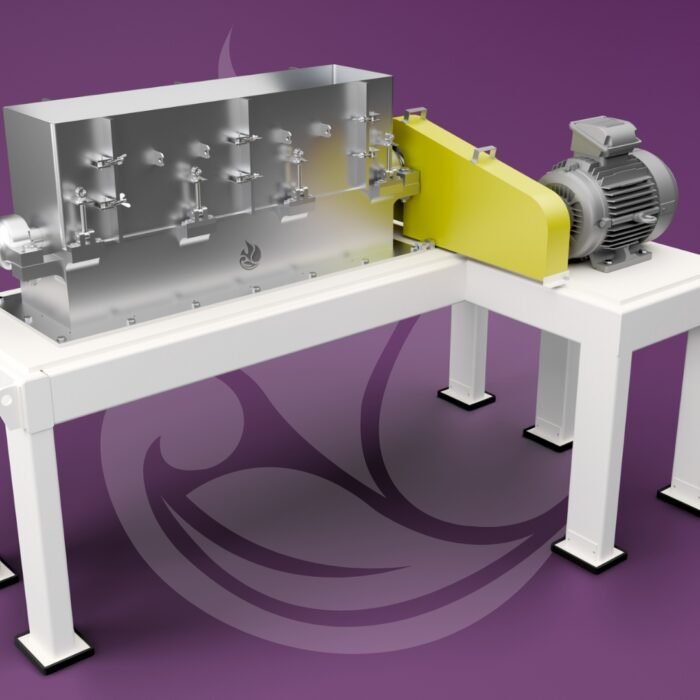

Size Reduction & Grinding Technologies

Particle size consistency defines product quality in industries such as food processing and pharmaceuticals. Whether producing fine turmeric powder or coarse spice blends, MillNest’s range of hammer mills and spice grinder machines ensures precise particle size control. The MillNest Hammer Mill is designed for high-speed grinding, ensuring uniform spice grinding with minimal heat generation. For applications requiring ultra-fine powders, MillNest integrates air classifier technology, delivering controlled fineness with maximum yield.

Sterilization & Microbial Control

Product safety and microbial contamination control are non-negotiable in industries such as pharmaceuticals and food processing. MillNest’s autoclave sterilizers offer an advanced approach to microbial decontamination, eliminating bacteria, mold, and spores without compromising the integrity of powdered products. The controlled temperature and pressure system ensure pathogen-free spices, herbal powders, and pharmaceutical ingredients, aligning with international safety standards for export markets.

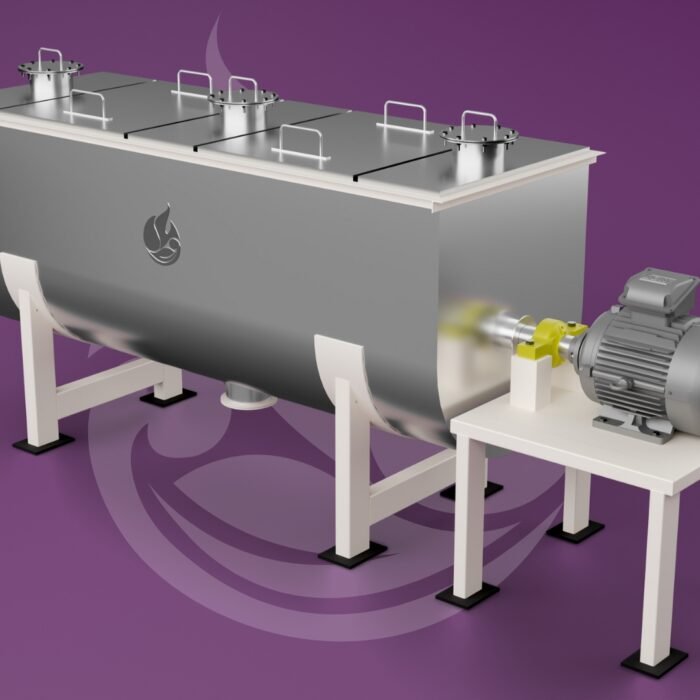

Drying & Cooling for Moisture Control

Moisture control is a critical factor in maintaining powder stability and preventing clumping. MillNest provides precision drying and cooling solutions, designed to remove excess moisture without affecting product quality. The result is extended shelf life, improved powder flowability, and enhanced product stability, critical for industries dealing with hygroscopic powders such as turmeric and nutraceutical blends.

Weighing & Batching Accuracy

Consistency in formulation is essential for achieving high-quality end products. MillNest integrates automated weighing and batching systems that ensure precise ingredient proportions in every batch. Whether processing spice blends, pharmaceutical powders, or food additives, these systems provide accuracy that meets global manufacturing standards.

Pioneering the Future of Dry Powder Processing

MillNest’s commitment to research and development drives continuous improvements in processing efficiency, sustainability, and automation. The company is actively investing in intelligent process control systems, AI-driven quality assurance, and energy-efficient manufacturing solutions to enhance productivity across industries.

One of the key focus areas for MillNest is sustainable processing solutions. Energy-intensive processes like spice grinding and turmeric powder processing require optimization to reduce carbon footprints while maintaining high yield efficiency. MillNest is pioneering eco-friendly solutions, including waste heat recovery systems and low-energy grinding technologies, that allow manufacturers to cut costs while adhering to environmental regulations.

The company is also expanding its global footprint, bringing its expertise in dry powder processing to international markets. By adapting its solutions to meet regional compliance and processing requirements, MillNest is ensuring that manufacturers worldwide benefit from its industry-leading technologies.

Conclusion: The MillNest Advantage

MillNest’s journey from a pioneering processing solutions provider to an industry benchmark in dry powder expertise is a testament to its commitment to innovation, quality, and efficiency. With proven success in spice grinding, pharmaceutical processing, and chemical manufacturing, the company continues to deliver cutting-edge solutions tailored to modern manufacturing demands.

By integrating pneumatic conveyor systems, hammer mills, autoclave sterilizers, and precision weighing technologies, MillNest offers a comprehensive processing ecosystem that enhances productivity, consistency, and sustainability.

For manufacturers seeking to elevate their dry powder processing capabilities, MillNest remains a trusted partner, driving efficiency, cost savings, and superior product quality. With a vision set on continuous improvement and global expansion, the future of dry powder processing is being shaped by MillNest’s expertise and technological advancements.