Spice Grinding Machines are revolutionising the heart of India’s spice belt, where Guntur holds legendary status for producing export-grade chilies known for their vibrant color and pungency. As local manufacturers gear up to meet rising global demand, there’s a growing realization that traditional equipment setups are no longer enough. Food safety regulations are tighter, energy costs higher, and export compliance more critical than ever.

For spice businesses in and around Guntur, the path to greater capacity, lower costs, and quality assurance is being led by a new generation of energy efficient spice grinding machines and turnkey processing solutions—as proven by one of the region’s most successful transformations.

This blog details how ITC Guntur, a leading spice processing unit, partnered with MillNest to modernize their facility under tight spatial and operational constraints—achieving significant improvements in efficiency, capacity, and compliance in just 45 days.

The Challenge: Limited Space, High Expectations

Many local spice factories in Guntur operate with space limitations, outdated machines, and legacy workflows. ITC Guntur was no different:

- Total available space: just 2,400 sq.ft

- Ceiling clearance: 5.5 meters (far below the 8-meter industry norm)

- Material handling infrastructure: 15 years old and incompatible with modern automation

Several top-tier vendors were approached—but declined due to space limitations. It was MillNest’s integrated engineering approach that changed the game.

MillNest’s Turnkey Engineering Solution

Rather than retrofitting parts, MillNest deployed an end-to-end plant redesign with precise process mapping. Their engineering consultancy and design strategy focused on:

1. Space Optimization Through Vertical Engineering

- Built a custom mezzanine structure using Z-axis elevation

- Compressed equipment footprints by 35% without sacrificing throughput

- Created a modular assembly layout for faster on-site integration

2. Smart Routing with Pneumatic Conveying Systems

- Replaced bulky belt conveyors with sealed pneumatic lines

- Reduced contamination risk, product loss, and manual transfer

Result:

A plant that originally required 4,000 sq.ft was redesigned to fit into 2,400 sq.ft—achieving a 40% increase in capacity without expanding the layout.

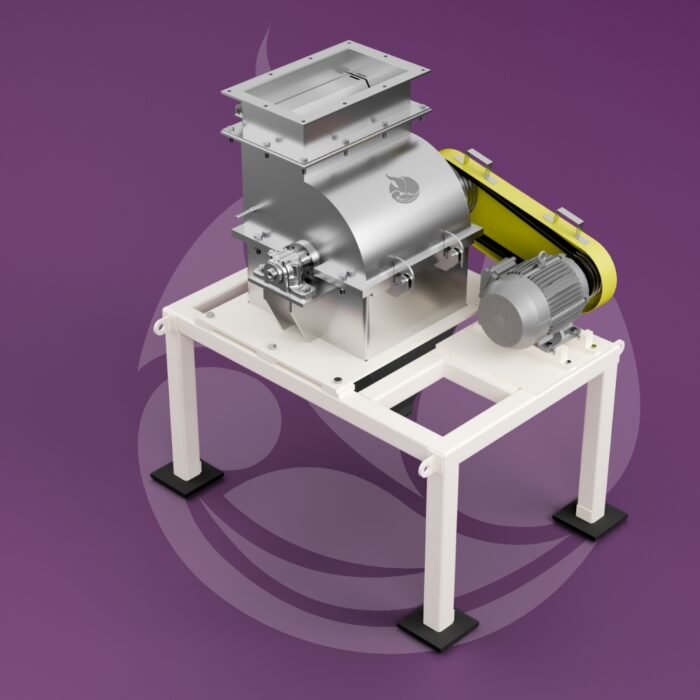

Equipment Spotlight: Tailored to Fit, Engineered to Perform

MillNest’s lineup of spice grinding machines included three fully customized machines to meet ITC Guntur’s unique footprint and performance goals.

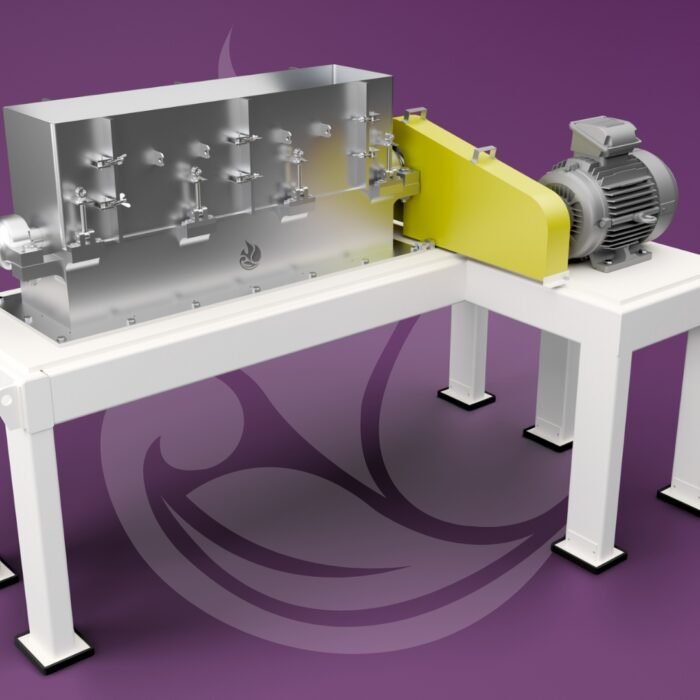

MCUT-2500-C Cutter Mill

Designed with a compact, low-height profile, the MCUT-2500-C is optimized for space-restricted facilities. Its modular footprint makes it ideal for mezzanine installations, while the dual-inlet blade system provides precise control for fibrous spices like turmeric and ginger. The re-engineered drive delivers consistent output with improved energy efficiency, ensuring reliability without occupying excess space.

- Footprint: Just 2.8 m²

- Capacity: Upgraded from 1.0 TPH to 2.0TPH

- Power Use: Cut to 40 HP

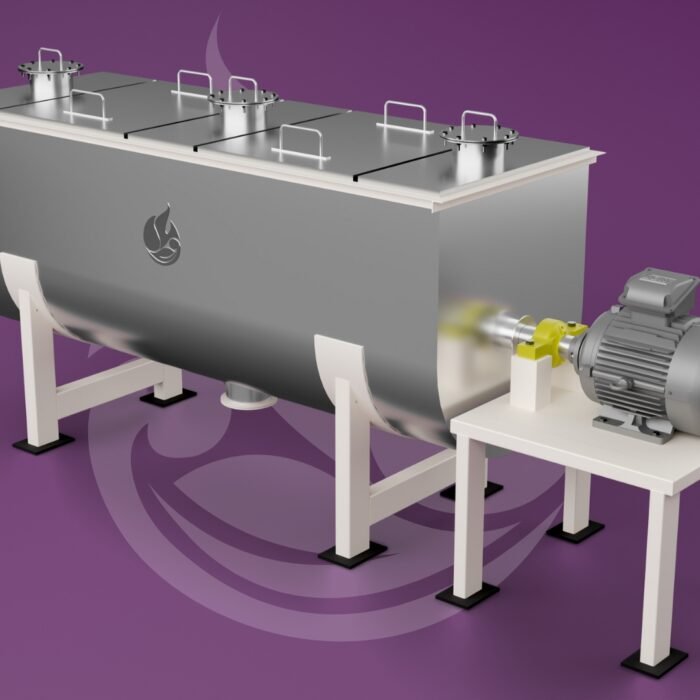

MRBL-3000-PLC Ribbon Blender

- Stores over 200 spice blend recipes

- Auto-correction: Adjusts weight in real-time ±0.1%

- Batch traceability: Essential for FSSAI compliance and export certification

Integration: Connected directly with ITC’s ERP, forming a seamless smart automated spice blending line.

Quality Wins

- Zero export rejections in 18 months

- Passed EU microbial standards

- 94% reduction in customer complaints

Verified Gains: Numbers That Matter

The transformation wasn’t just technical—it delivered significant financial and operational wins.

Production Metrics

| KPI | Before | After |

|---|---|---|

| Capacity | 1 TPH | 1.7 TPH |

| Energy Use for grinder | 0.203 kW/ton | 30.184 kW/ton |

Local Learnings: Why Guntur Businesses Should Pay Attention

This case study reflects the immense opportunity for local spice manufacturers in Guntur. Even under spatial and infrastructure constraints, with the right partner, you can:

- Upgrade to sustainable processing without factory expansion

- Achieve dust control in milling for improved safety and hygiene

- Integrate automated spice packaging lines and conveyors

- Scale output, minimize energy use, and comply with global standards

MillNest’s custom engineering goes far beyond off-the-shelf equipment. Whether you run a chili powder unit or a contract export business, our solutions adapt seamlessly to your layout, product mix, and ROI targets.

Compliance with Industry Standards and Regulations

Ensuring that your spice processing facility meets all local and international food safety and quality standards is critical. The Guntur spice industry operates under strict guidelines set by government authorities to maintain export quality and consumer safety. Leveraging MillNest’s advanced spice grinding machines helps you stay compliant by adopting energy-efficient, hygienic, and precise processing technologies.

For detailed information about the regulatory standards and compliance requirements for spice processing in India, you can refer to the official guidelines provided by the Spices Board of India.

Ready to Transform? MillNest Can Help.

MillNest offers end-to-end processing plant support—from site audits to design, installation, and training. Their track record in Guntur, India, and across Southeast Asia makes them the go-to partner for any scale of operation.

What You Get in the Free Audit

- Plant layout and capacity enhancement review

- Dust control, safety, and compliance inspection

- ROI roadmap using real case benchmarks

- Retrofit and automation feasibility

📞 Call: +91-7330000371

📧 Email: sales@millnest.com

🌐 Visit: www.millnest.com

Your partner in bulk material handling equipment, food-grade pneumatic conveying systems, pulverizer machines, and commercial spice mills—trusted by India’s top processors.