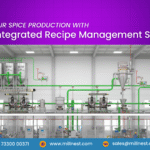

The spice processing industry demands precision, efficiency, and adherence to stringent quality standards. For businesses looking to establish or upgrade their spice processing facilities, turnkey solutions offer a streamlined path from concept to commercial production. This comprehensive guide explores how turnkey spice processing solutions can transform your business vision into a fully operational reality.

What Are Turnkey Spice Processing Solutions?

Turnkey spice processing solutions represent a complete, end-to-end approach to establishing a spice processing facility. The term “turnkey” signifies that the provider handles every aspect of the project—from initial planning and design to equipment installation and final commissioning—delivering a ready-to-operate facility.

Unlike piecemeal approaches where you coordinate with multiple vendors for different components, a turnkey solution provides a single point of responsibility. The provider manages plant design, equipment procurement, civil works coordination, installation, testing, and staff training, ensuring seamless integration of all processing systems.

For spice processors, this means receiving a complete processing line capable of handling operations like cleaning, grinding, blending, sterilization, and packaging under one unified project framework. The facility is handed over only when it’s fully operational and meeting predetermined performance parameters.

Benefits for Spice Processors

Single-Point Accountability

Working with one provider for your entire spice processing plant eliminates the coordination challenges of managing multiple vendors. This unified responsibility ensures better project oversight, faster problem resolution, and clearer communication throughout the implementation process.

Optimized System Integration

Turnkey providers design each component to work harmoniously within the complete processing line. This integration ensures optimal material flow, minimizes bottlenecks, and maximizes processing efficiency—critical factors in maintaining spice quality and production throughput.

Reduced Implementation Time

With streamlined project management and pre-engineered solutions, turnkey implementations significantly reduce the time from planning to production. The provider’s experience in executing similar projects translates to faster deployment and earlier revenue generation for your business.

Quality Assurance Throughout

Comprehensive quality control measures applied across all project phases ensure that equipment, installation, and commissioning meet industry standards. This systematic approach reduces the risk of equipment failures and processing inconsistencies that could impact product quality.

Cost Predictability

Turnkey solutions typically involve fixed-price contracts that provide clear visibility into total project costs. This predictability helps with financial planning and eliminates the budget overruns common in projects involving multiple contractors.

Technical Expertise Access

Leveraging the provider’s accumulated knowledge from multiple installations gives you access to best practices, proven technologies, and industry insights that might take years to develop independently.

The Planning Phase: Foundation of Success

Initial Consultation and Requirement Analysis

The journey begins with understanding your specific processing needs, production capacity targets, product range, quality standards, and budget parameters. This consultation phase involves detailed discussions about your business objectives, market requirements, and growth projections.

A thorough site assessment examines available space, utilities infrastructure, material handling logistics, and regulatory compliance requirements. This evaluation identifies potential challenges early and informs the overall plant design strategy.

Conceptual Design Development

Based on requirement analysis, the provider develops conceptual layouts showing equipment placement, material flow paths, utility connections, and operational workflows. These preliminary designs balance processing efficiency with space optimization and future expansion possibilities.

The conceptual phase also includes capacity modeling to ensure the proposed configuration meets your production targets while maintaining flexibility for product variations and volume fluctuations.

Detailed Engineering and Approvals

Once the concept is approved, detailed engineering translates the vision into actionable specifications. This includes equipment specifications, piping and instrumentation diagrams, electrical layouts, civil requirements, and compliance documentation.

This phase produces the complete technical documentation needed for procurement, construction, and regulatory approvals, ensuring all stakeholders have a clear roadmap for implementation.

Equipment Selection: The Heart of Your Operation

Processing Equipment Portfolio

Selecting appropriate equipment forms the core of any spice processing facility. Key components typically include:

Cleaning Systems: Advanced cleaning equipment removes impurities, foreign materials, and defective spices, ensuring only quality raw materials enter the processing line. Technologies may include destoners, magnetic separators, and gravity separators tailored to different spice characteristics.

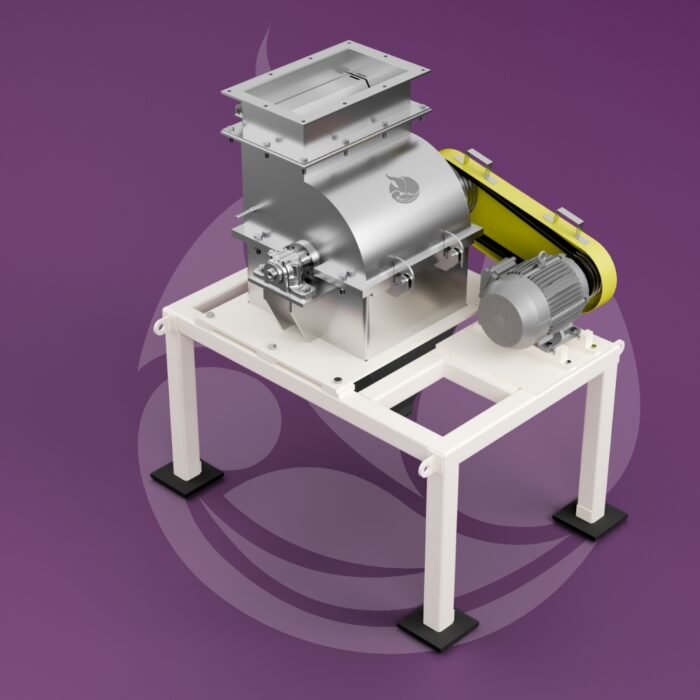

Grinding and Milling: Precision grinding equipment produces consistent particle sizes critical for spice quality and customer specifications. Modern grinding systems incorporate temperature control to preserve volatile oils and maintain color integrity.

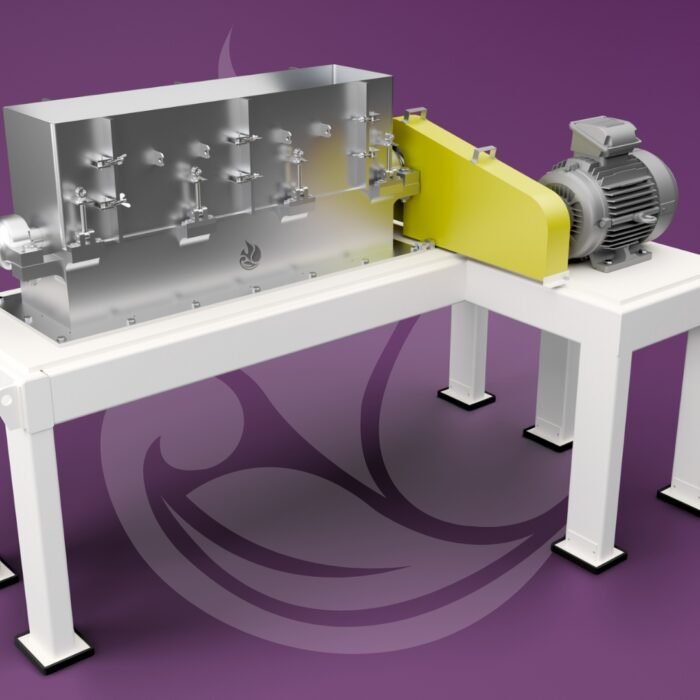

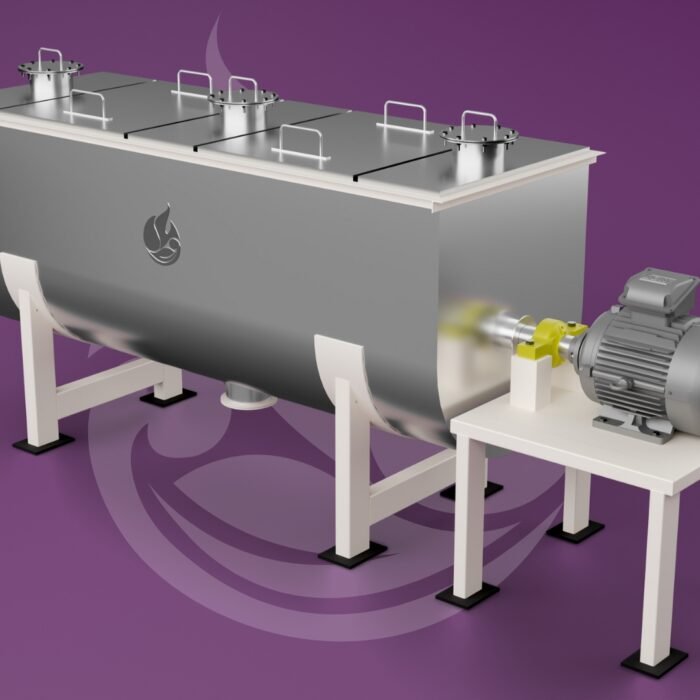

Blending Systems: Accurate blending equipment ensures uniform mixing of spice formulations, maintaining consistency across production batches. Advanced systems provide precise control over mixing parameters and batch traceability.

Sterilization Technologies: Meeting food safety standards requires effective sterilization systems that eliminate microbial contamination while preserving spice characteristics. Various technologies address different processing requirements and regulatory standards.

Packaging Solutions: Automated packaging systems maintain product freshness, ensure accurate filling, and improve production efficiency. Options range from basic filling systems to sophisticated automated lines with integrated quality checks.

Customization for Specific Needs

Every spice processing operation has unique requirements based on product mix, production volumes, and market demands. Equipment selection considers factors like spice varieties processed, moisture content variations, particle size requirements, and packaging formats.

Customization ensures equipment specifications align with your operational needs rather than forcing your processes to fit standard configurations.

Quality and Compliance Standards

All equipment should meet relevant food processing standards and regulatory requirements. This includes food-grade construction materials, hygienic design principles, safety features, and documentation supporting compliance verification.

The Installation Process: Bringing Plans to Life

Site Preparation and Civil Works

Before equipment arrival, proper site preparation ensures smooth installation. This includes civil works like foundation preparation, floor finishing, drainage systems, and structural modifications required for equipment mounting.

Coordination with civil contractors ensures infrastructure readiness when equipment is delivered, preventing delays and installation complications.

Equipment Installation and Integration

Systematic installation follows detailed engineering drawings and manufacturer specifications. Each component is positioned, leveled, and anchored according to design requirements, with particular attention to alignment and accessibility for operation and maintenance.

Integration involves connecting equipment through material transfer systems, establishing utility connections for power and water, and implementing control systems that enable coordinated operation across the processing line.

Testing and Validation

Rigorous testing verifies that installed equipment operates according to specifications. This includes individual equipment testing, integrated system trials, and process validation runs using actual materials.

Testing identifies and resolves any performance issues before commercial production begins, ensuring the facility meets design parameters and quality standards.

Commissioning: Transition to Production

Systems Commissioning

Commissioning represents the final verification phase where all systems are operated under actual production conditions. This comprehensive process confirms that equipment, controls, utilities, and safety systems function as designed.

Commissioning activities include calibration verification, control system validation, safety interlock testing, and performance confirmation against design specifications.

Staff Training

Effective operation requires properly trained personnel. Comprehensive training programs cover equipment operation, maintenance procedures, quality control protocols, safety practices, and troubleshooting techniques.

Hands-on training during commissioning allows operators to gain practical experience under expert guidance, building confidence and competence before independent operation begins.

Performance Verification

Final performance verification involves running extended production trials to demonstrate that the facility consistently meets capacity, quality, and efficiency targets. Documentation of successful performance trials provides confidence that the investment will deliver expected returns.

Post-Installation Support: Ensuring Long-Term Success

Technical Support and Troubleshooting

Ongoing technical support ensures quick resolution of any operational issues that arise after commissioning. Access to experienced technical teams minimizes downtime and maintains production continuity during the critical early operational phase.

Spare Parts and Maintenance

Reliable spare parts availability and preventive maintenance guidance protect your investment and ensure consistent operation. Structured maintenance programs help optimize equipment lifespan and maintain processing quality over time.

Process Optimization

As operations stabilize, process optimization initiatives can enhance efficiency, reduce waste, and improve product quality. Continuous improvement support helps maximize returns from your processing investment.

Upgrades and Expansion Support

As your business grows, expansion support ensures new capacity integrations maintain system harmony and processing standards. This continuity simplifies scaling operations while preserving operational consistency.

ROI Analysis: Understanding Your Investment Returns

Capital Investment Components

Understanding the complete investment picture helps evaluate returns accurately. Turnkey solutions encompass equipment costs, installation expenses, engineering services, commissioning activities, and initial training—providing a comprehensive view of capital requirements.

Operational Cost Considerations

Beyond capital investment, operational efficiency impacts ongoing profitability. Modern equipment typically offers advantages in labor efficiency, energy consumption, material yield, quality consistency, and maintenance requirements compared to older technologies or manual processes.

Revenue Impact Factors

Return calculations should consider production capacity increases, quality improvements enabling premium pricing, expanded product range capabilities, reduced waste and rework, and faster time-to-market for new products.

Break-Even and Payback Analysis

Most spice processing investments achieve payback within two to four years, depending on production volumes, product margins, and operational efficiency gains. The predictability of turnkey solutions—with clear performance parameters and defined costs—enables more accurate financial projections than fragmented approaches.

Competitive Advantages

Beyond direct financial returns, modern processing facilities provide competitive advantages through quality consistency, regulatory compliance, scalability, and the ability to meet evolving customer requirements in food safety and traceability.

Why Choose Millnest for Your Turnkey Spice Processing Solution

Millnest brings specialized expertise in spice processing equipment and complete plant solutions to businesses across India and beyond. With a comprehensive understanding of spice processing challenges and requirements, Millnest delivers integrated solutions that address the complete spectrum of processing needs.

Comprehensive Equipment Portfolio

Millnest offers a complete range of spice processing equipment designed specifically for the unique characteristics and requirements of spice processing operations. From cleaning and grinding to blending and packaging, every component is engineered for reliability, efficiency, and quality output.

End-to-End Project Management

Taking full responsibility for project execution, Millnest manages every phase from initial consultation through final commissioning. This unified approach eliminates coordination complexities and ensures all elements work together seamlessly.

Industry Experience and Expertise

Deep knowledge of spice processing technologies, industry standards, and operational best practices informs every project. This experience translates to practical solutions that address real-world processing challenges while meeting regulatory requirements.

Quality-Focused Approach

Commitment to quality permeates every aspect of Millnest’s turnkey solutions—from equipment selection and installation to testing and validation. This quality focus ensures facilities meet stringent food processing standards and deliver consistent product quality.

Customer-Centric Solutions

Understanding that every business has unique requirements, Millnest develops customized solutions aligned with specific production needs, budget parameters, and growth objectives rather than offering one-size-fits-all packages.

Ongoing Partnership

The relationship extends beyond installation, with continued technical support, maintenance guidance, and expansion assistance ensuring long-term success. This partnership approach helps clients maximize their processing investment over the facility’s entire operational life.

Taking the Next Step

Establishing or upgrading a spice processing facility represents a significant business decision with long-term implications for operational efficiency, product quality, and competitive positioning. Turnkey solutions offer a proven path to successful implementation, combining comprehensive planning, integrated equipment systems, expert installation, and ongoing support.

For businesses seeking to enter spice processing or expand existing capabilities, partnering with an experienced turnkey solution provider like Millnest ensures your investment translates into a productive, efficient, and quality-focused processing operation.

The journey from planning to production becomes manageable when you have the right partner guiding every step—from initial concept through successful commercial operation and beyond.

Ready to explore turnkey spice processing solutions for your business? Contact Millnest to discuss your specific requirements and discover how a comprehensive, integrated approach can transform your spice processing capabilities.