In retrofitting spice processing, scaling output doesn’t always mean buying new machines. In fact, many mid-sized and legacy spice factories can unlock higher throughput, better consistency, and lower energy use simply by retrofitting the right components into their existing systems.

Retrofitting is no longer just about replacing worn-out parts. It’s a strategic approach to process improvement—targeting critical zones in the production line where performance bottlenecks occur. Whether you’re looking to improve your spice grinder machine, streamline mixing, or reduce energy costs during masala grinding, the key lies in upgrading with precision. That’s where MillNest’s retrofit-ready systems and components come into play, especially when paired with robust maintenance services and high-quality spares.

This blog explores seven high-impact retrofit spice processing add-ons that significantly improve output, yield, hygiene, and energy efficiency across spice processing lines.

Why Retrofit Spice Processing Works for Output Gains

For many spice manufacturers, challenges like inconsistent granule size, increased downtime, and inefficient grinding cycles are ongoing hurdles. These issues often stem not from poor operations but from aging systems and components that weren’t built to meet today’s scale or quality demands.

Rather than investing in an entirely new setup, retrofitting specific parts of your production line can provide targeted improvements. This is especially relevant for operations wondering how to increase output in a spices factory without a major capital investment. Modern retrofit kits are engineered for compatibility, performance, and rapid deployment—helping operators improve batch sizes, processing speed, and energy usage without compromising product quality.

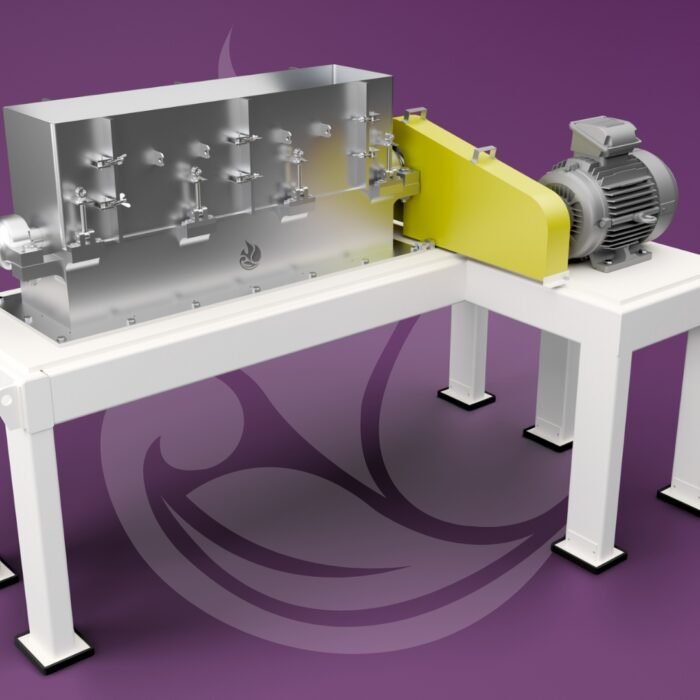

1. MillNest Hammer Mill : Sharpening the Heart of Grinding

The hammer is the central force behind any hammer mill’s grinding efficiency. Over time, these hammers wear down, leading to uneven particle sizes, reduced throughput, and higher energy draw.. Upgrading to MillNest’s hammer mill hammers improves spice particle uniformity, reduces powder waste, and extends wear life. These upgrades reduce replacement frequency and restore the grinding power your spice grinder machine was designed to deliver.

The MHAM (MillNest Hammer Mill) is retrofit-compatible and designed to accept high-durability hammers that withstand demanding spices like turmeric, cumin, and chili. These upgraded hammers not only offer longer wear cycles but also improve cutting impact, reducing powder wastage and enhancing granule consistency. It’s a fast, high-ROI retrofit for any spice grinding machine.

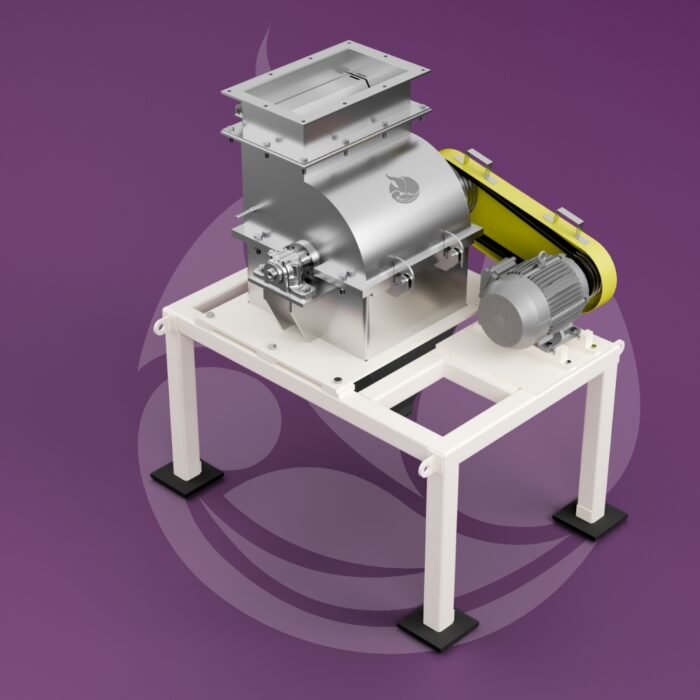

2. Classifier Wheels: The Upgrade Behind Precision Powder

One of the most overlooked retrofit components is the classifier wheel—especially in advanced systems like MillNest’s MACM (Air Classifier Mill). These wheels determine how finely ground spices are separated and discharged, directly impacting yield, texture, and application consistency.

A worn-out classifier wheel often leads to overgrinding, increased energy use, and inconsistent powder distribution. Retrofitting a new wheel enables more accurate particle separation, reducing reprocessing cycles and ensuring every spice batch meets quality standards. This upgrade is critical in facilities focused on high-grade masala or seasoning blends.A fresh wheel retrofit improves airflow, granule size accuracy, and overall powder quality—ideal for premium masala lines targeting export markets.

3. Filter Bags: Better Hygiene, Higher Recovery

In spice plants where hygiene and air quality are paramount, filter bags play a crucial role. These components capture ultra-fine spice dust during grinding, preventing product loss and keeping the production environment clean.

Ensuring hygiene and compliance with food safety standards is critical during retrofit spice processing. For more details on industry regulations, you can refer to the Food Safety and Standards Authority of India (FSSAI) guidelines on spice handling and processing

Old or clogged filter bags can choke airflow, reduce suction efficiency, and cause cross-contamination—especially in spice lines with frequent batch changeovers. Retrofitting with high-efficiency filter bags not only boosts powder recovery but also ensures compliance with export hygiene standards. This small change can make a big difference in energy usage and product integrity.

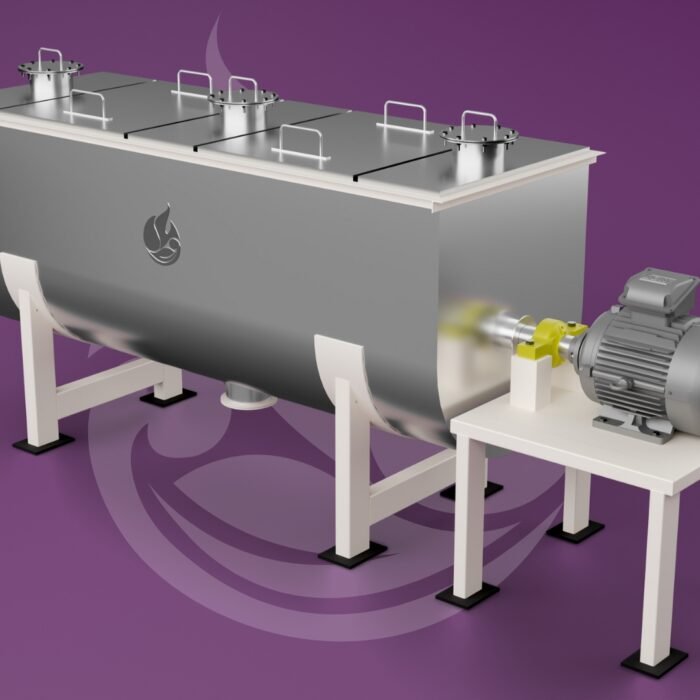

4. Blenders Machine: Retrofit Upgrades for Uniform Spice Mixing

Consistent spice blends rely heavily on effective mixing. However, many older ribbon or paddle blenders develop dead zones or uneven dispersion due to worn blades and outdated designs. MillNest’s blenders machine retrofits come in—featuring improved shafts, variable-speed motors, and clean-in-place designs that can dramatically enhance mixing quality.

When processors retrofit their blending stations, particularly in grinding machines for masala lines, they often notice reduced batch time, fewer re-runs, and improved flavor uniformity. MillNest offers paddle and ribbon blender retrofits engineered for high-volume production with minimal downtime. Retrofitting your blending line—especially for a grinding machine for masala setups—ensures faster mix times, better dispersion, and consistent seasoning output, even at scale.

5. Bearing Bushes and Sleeves: Quiet Boost to Stability

Spice grinding is a high-vibration process. Over time, the mechanical parts that stabilize moving components—like bearing bushes and sleeves—wear down. This leads to shaft misalignment, excessive noise, and reduced equipment lifespan. MillNest’s quality spare parts for grinding machines, including retrofit-ready bearing bushes, bring stability back to your grinding and blending systems.

Replacing these with MillNest’s retrofit-grade bearing components restores mechanical precision to your grinders and blenders. The result? Higher machine uptime, smoother operation, and consistent product flow. Though often ignored, these retrofits are foundational to long-term output reliability.

6. Air Classifier Mill Upgrade: Powering Precision & Energy Savings

For spice plants using air classifier technology, retrofitting the mill itself—particularly the rotor, liners, and internal airflow controls—can yield substantial efficiency gains. MillNest’s MACM system is retrofit-compatible and designed for seamless upgrades.

By enhancing air flow regulation and particle cutoff accuracy, a retrofitted air classifier mill produces more consistent powder granulation with less overprocessing. This upgrade directly impacts how to increase output in a spices factory, especially when scaling premium product lines.

7. Predictive Maintenance Systems: Essential for Retrofit Spice Processing Efficiency

No retrofit strategy is complete without addressing downtime. One of the smartest retrofit spice processing add-ons today is the integration of control panels with sensors that enable predictive maintenance. These systems monitor machine health, track wear on components like hammers or filter bags, and alert operators before failures occur.

For facilities dealing with unpredictable breakdowns, adding predictive tools improves planning, reduces emergency repairs, and ensures critical parts like spare parts for grinding machines are available before they’re needed. Combined with MillNest’s maintenance services, this creates a self-sustaining performance loop.

Retrofitting with MillNest: Performance with Precision

At MillNest, retrofitting is more than a one-time fix—it’s a forward-looking approach to plant growth. Our systems like MHAM and MACM are built to scale and adapt with retrofit-compatible parts and automation-ready components. From blenders machine enhancements to high-durability spare parts, MillNest delivers integrated solutions that improve yield, reduce energy use, and uphold quality standards.

We also provide expert maintenance services and quality spare parts designed to extend equipment life, ensuring that your retrofit investment continues to perform.

Conclusion: Build Better from What You Have

You don’t need to replace your entire line to boost plant performance. Sometimes, the fastest and most cost-effective way to scale is to upgrade what matters—whether it’s a hammer, a filter, or a control panel.

By targeting high-impact zones in your grinding, blending, and conveying processes, and working with a partner like MillNest, you can turn aging infrastructure into a high-performing spice production line.

Looking to plan your next retrofit upgrade? Start with a performance audit—and discover which retrofit spice processing add-ons will transform your plant’s output from the inside out.