Hygienic food processing equipment plays a vital role during the festive season when food manufacturers face soaring demand and rapid product changeovers. The festive period is a golden opportunity for manufacturers—demand can triple overnight—but with that surge comes a critical challenge: processing multiple products back-to-back while guaranteeing zero contamination.

In this high‑pressure environment, hygienic equipment design is not a luxury; it is the backbone of food safety. This blog dives into how purpose‑engineered, contamination‑free food machinery enables safe, efficient, and compliant processing during the festive rush. We’ll explore contamination prevention, rapid changeover techniques, and robust cleaning protocols—backed by insights from Millnest Academy experts.

The Contamination Problem in Multi‑Product Plants

When you switch from producing pumpkin spice mixes to chocolate coated nuts—or from dairy‑based desserts to allergen‑free biscuits—cross‑contamination becomes the biggest threat. Contamination isn’t limited to visible residue; it can be:

- Allergen carry‑over – A trace of peanuts in a nut‑free product can trigger severe reactions.

- Flavour and odour transfer – Strong spices (e.g., cinnamon, clove) can linger and spoil a neutral‑flavour item.

- Microbial growth – Moisture trapped in equipment crevices creates a breeding ground for pathogens.

- Powder residue – Fine powders from spice blending or powder mixing can settle on adjacent product streams, altering nutritional content and safety.

Engineering Food Safety Through Hygienic Food Processing Equipment — The Millnest Way

At Millnest, we integrate food safety compliance directly into the design of every piece of equipment. Below are the core engineering principles that safeguard multi‑product operations:

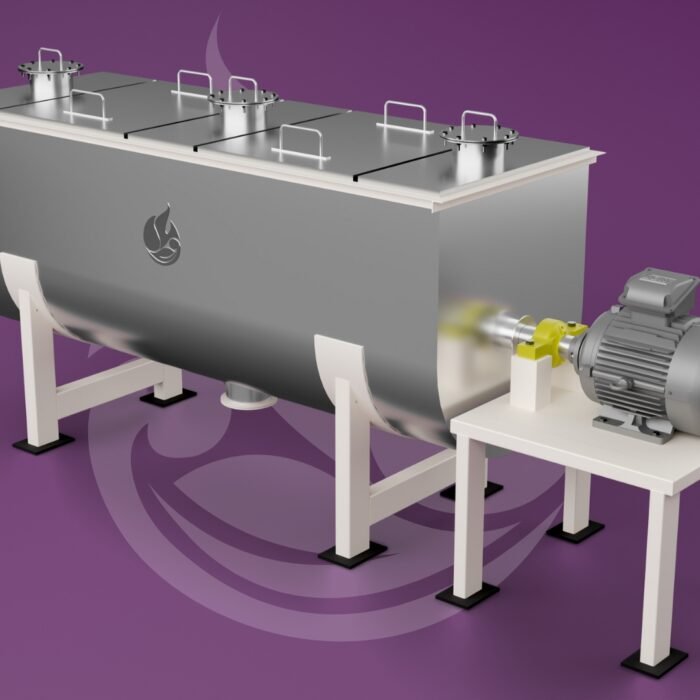

1. Seamless, Hygienic Surface Finishes

- Electropolished Stainless Steel (Ra ≤ 0.8 µm):

A mirror‑like finish reduces the surface area for particles to adhere. It also simplifies cleaning—water and sanitisers spread evenly, leaving no hidden corners for residue. - Smooth Welds & No Crevices:

Lap welds are eliminated. All joints are full‑penetration, butt welds that are ground smooth. This removes potential traps for powder or moisture.

2. Sealed Components & Bearings

- Hygienic Seals & Gaskets:

Utilising sanitary EPDM or PTFE gaskets, we ensure that joints remain tight even under high pressure and temperature variations. This prevents leaks and external contamination. - Sealed Bearings:

Bearings are encapsulated in food‑grade, stainless‑steel housings. Traditional grease can contaminate product; our design uses oil‑free, ceramic bearings or sealed units that never expose lubricants.

3. Dead‑Zone‑Free Design

Dead zones—areas where product can sit undisturbed—are contamination hotspots. Hygienic Food Processing Equipment features:

- Continuous Flow Paths:

In powder mixing and spice processors, the internal geometry ensures that every particle is moved, mixed, and discharged without stagnation. - Conveyors with No Accumulation Pockets:

Belt cleaners and scraper blades keep the surface clear, preventing powder build‑up.

4. Automation & Recipe Management

Modern food safety compliant processing equipment incorporates PLC‑based recipe control. During festive seasons, operators load a new recipe, and the system:

- Automatically flushes the line with a sanitising solution.

- Executes a pre‑set clean‑in‑place (CIP) cycle before starting the next product.

- Logs every step for traceability—critical for audits and rapid issue resolution.

Result: Human error is minimised, and each product change is a controlled, contamination‑free transition.

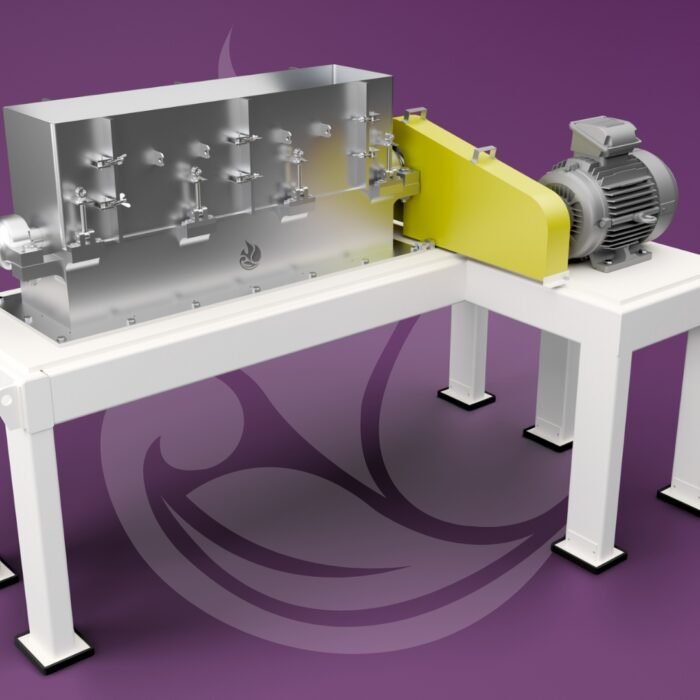

5. Hygienic Spice Processing Machinery

Spices are potent allergens and flavour carriers. Millnest’s Hygienic Food Processing Equipment includes:

- Encapsulated Blending Chambers:

No external dust emission; airlocks prevent cross‑contamination from the environment. - Integrated Dust Extraction:

HEPA‑filtered exhaust systems capture even the finest powder particles, keeping the workspace clean and safe.

Quick Changeover Techniques for Zero Downtime

Festive season profitability depends on maximizing production uptime while maintaining absolute contamination control. This requires rethinking traditional changeover approaches that prioritize thoroughness over speed.

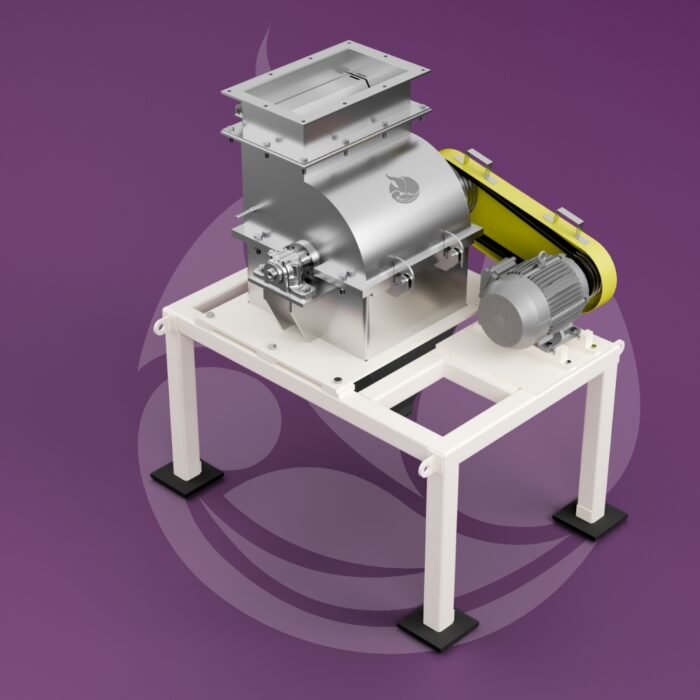

Quick-release mechanisms transform hour-long disassembly procedures into 10-minute operations. Tri-clamp connections replace threaded fasteners, allowing single-person component removal without tools. Modular mixer bowls lift out via overhead hoists, enabling offline cleaning while alternate bowls maintain production.

The key innovation lies in designing easy-to-clean food processing equipment where cleaning occurs in-place without disassembly. Clean-in-place (CIP) systems deliver precisely controlled cleaning solutions through strategically positioned spray heads. Automated valve sequencing ensures complete surface coverage while preventing cross-contamination between cleaning zones.

A practical festive changeover workflow demonstrates these principles in action. Upon batch completion, the mixer automatically purges residual product through pneumatic discharge valves. CIP systems activate immediately, delivering alkaline detergent through high-impact spray balls while mixer blades rotate at cleaning speed. Rinse cycles remove detergent residues, followed by sanitizer application and final rinse. Throughout this 25-minute cycle, operators prepare the next batch ingredients, enabling immediate production restart upon cleaning completion.

Validation systems confirm cleaning effectiveness before production authorization. ATP swabs detect organic residues while visual inspection confirms absence of visible contamination. Only after validation approval can operators load new ingredients, ensuring zero cross-contamination between products.

Advanced Contamination Control: Beyond Basic Hygiene

Modern multi-product facilities require sophisticated contamination control that extends beyond individual equipment pieces to encompass entire processing environments. This system’s approach addresses airborne contamination, environmental factors, and human interface points that traditional hygiene focuses often overlook.

Positive pressure systems prevent external contamination ingress while controlling internal air patterns. Processing areas maintain higher pressure than surrounding zones, ensuring airflow direction moves from clean to potentially contaminated areas. High-efficiency particulate air (HEPA) filtration removes particles down to 0.3 microns, eliminating airborne cross-contamination between processing lines.

Material handling systems integrate seamlessly with food processing equipment with quick changeover capabilities. Pneumatic conveying utilizes dedicated pipelines for different product categories, preventing cross-contamination during transport. Automated cleaning systems purge convey lines between products using compressed air sequences followed by vacuum evacuation.

Powder mixing operations require particular attention to electrostatic control. Static electricity generation during high-speed mixing can cause particle adhesion to vessel walls, creating contamination sources that persist through cleaning cycles. Conductive mixer designs and grounding systems dissipate static charges, preventing particle attraction and enabling complete product discharge.

Hygienic Food Processing Equipment Cleaning Protocols: Design Enables PerformanceHygienic Cleaning Protocols: Design Enables Performance

Effective cleaning depends entirely on equipment design that provides access, eliminates dead zones, and promotes drainage. Traditional approaches that rely on manual scrubbing and solvent wiping cannot achieve the contamination levels required for safe multi-product processing.

Hygienic cleaning systems integrate into equipment design from initial conceptualization. Internal mixer geometries incorporate smooth transitions between surfaces, eliminating sharp corners where cleaning solutions cannot penetrate. Mixer blade designs feature hollow construction that allows internal cleaning solution circulation, ensuring complete sanitization of product contact surfaces.

Cleaning solution chemistry requires matching to specific contamination types. Protein-based residues respond to alkaline cleaners that break peptide bonds. Oil and fat contamination requires surfactant-based solutions that emulsify lipid deposits. Mineral residues from spice processing need acidic cleaners that dissolve inorganic deposits. Automated dosing systems ensure precise chemical delivery while preventing operator exposure to hazardous cleaning compounds.

Temperature control during cleaning cycles dramatically improves effectiveness. Heated cleaning solutions increase chemical activity and reduce viscosity, improving penetration into contaminated areas. Our hygienic processing systems incorporate steam injection that raises cleaning solution temperatures to 75°C, optimizing cleaning kinetics while maintaining equipment integrity.

Millnest Academy Insights: Expert Perspectives on Contamination Control

Through extensive collaboration with food safety professionals, several critical insights have emerged that distinguish successful festive processing operations from those that struggle with contamination issues.

The most significant finding involves validation timing. Traditional approaches validate cleaning effectiveness after completion, discovering contamination when corrective action becomes expensive and time-consuming. Leading operations implement real-time validation using inline sensors that detect contamination during cleaning cycles. This enables immediate corrective action while cleaning systems remain active.

Allergen control requires special consideration beyond general contamination prevention. Allergenic proteins exhibit strong adhesion properties that resist standard cleaning. Dedicated processing lines for allergenic products prevent cross-contamination more effectively than shared equipment with enhanced cleaning. When shared lines are unavoidable, protein-specific cleaning validation using ELISA testing ensures allergenic protein removal below detection thresholds.

Training protocols significantly impact contamination control effectiveness. Operators must understand the scientific principles behind cleaning procedures, not just follow procedural checklists. Understanding why specific cleaning temperatures, contact times, and chemical concentrations are required enables operators to recognize when procedures require adjustment for different contamination types.

Five Steps to Ensure Zero Cross-Contamination in Festive Processing

- Equipment Qualification: Verify that all processing equipment meets hygienic design standards with documented surface finish specifications, seamless construction, and complete drainage capability.

- Cleaning Validation: Establish baseline contamination levels through comprehensive testing and validate cleaning procedures using worst-case contamination scenarios.

- Process Control: Implement automated systems that prevent equipment operation until cleaning validation confirms contamination-free status.

- Environmental Monitoring: Establish air quality controls and material handling procedures that prevent external contamination sources.

- Continuous Verification: Deploy real-time monitoring systems that detect contamination during processing and cleaning operations.

Engineering Success into Festive Operations

The festive season represents the ultimate test of food processing capabilities. Success requires recognizing that food safety cannot be inspected into products—it must be engineered into every aspect of processing operations. From initial equipment specification through daily cleaning protocols, every decision impacts contamination control effectiveness.

Hygienic Food Processing Equipment design provides the foundation for safe multi-product processing. Quick changeover capabilities enable profitable production scheduling. Automated cleaning systems ensure consistent contamination control. Together, these elements create processing environments where festive demand increases profits rather than risks.

The investment in proper hygienic design pays dividends throughout the operating lifecycle. Reduced cleaning time increases production capacity. Fewer contamination incidents eliminate costly rework and recalls. Enhanced product quality strengthens brand reputation during critical selling periods.

For manufacturers serious about conquering festive season challenges while maintaining uncompromising food safety standards, the path forward requires partnering with equipment suppliers who understand that contamination control begins at the drawing board, not the cleaning station.