In high-volume spice manufacturing, efficiency is no longer just a metric—it’s a strategic advantage. From energy consumption to space optimization and hygiene, modern automatic spice plants are rethinking every element of their operations. Next‑generation spice grinding machines and masala mixing machines—from the MillNest Air Classifying Mill (MACM) to MillNest Ribbon Blender (MRBL)—have shifted from optional upgrades to core decision‑making tools for growth.

This blog explores how industrial-scale players in India are using these grinding machines to achieve real, measurable improvements. Bringing you two plant-level transformations, we’ll break down how MillNest’s machinery delivers better output, cleaner processes, and lower costs—making it a strategic priority not just an operational choice.

The Efficiency Equation in Spice Processing

Efficiency in spice plants now gets assessed through:

- Output per square meter—measuring yield relative to real estate footprint

- Energy per kilogram processed—evaluating utility consumption within production

- Downtime hours per month—accounting for cleaning, maintenance, and changeovers

- Product consistency across batches—a must for export standards and brand reliability

Legacy grinders and mixers often fall short: they occupy more space, consume high power, and produce inconsistent particle size. Worse, thermal stress during processing can degrade aroma and color—critical quality parameters for spices. That’s why smart processors are transitioning to industrial spice grinding machines and energy-efficient milling systems, where smart airflow, controlled rotors, and precise size reduction deliver better consistency, higher yield, and cleaner operations.

Case Study: Onion Powder & Granules at European Dehydrated (Mahuva)

Setup: A compact 28 m² plant in Gujarat

Equipment:

- MillNest Air Classifying Mill (MACM‑30 HP and MACM‑60 HP)

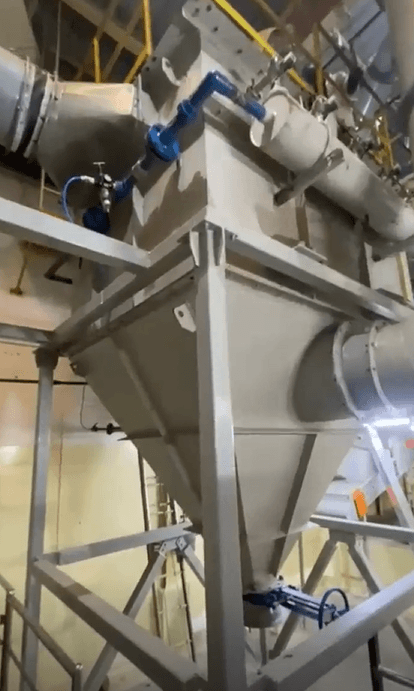

- Cyclone separator → bag filter → micro‑sifter → blending unit

Results Achieved:

- Granules output: 400–450 kg/hr; powder: 750–800 kg/hr

- Power draw cut by 25% from old hammer mills

- Product kept within ambient +10 °C, preserving aroma and color

- Flexibility: a single machine used alternately for both powder and granule formats

- Lower labor demand and compact layout thanks to automation and closed loops

This facility’s upgrade shows how a modern spice ginding machines, designed with classification and airflow control, can deliver both quantity and quality in minimal space.

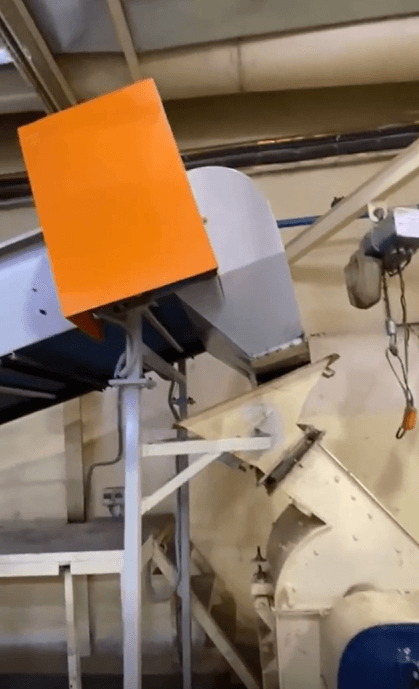

Case Study: Chili Cleaning Line Upgrade at Olam (Kochi)

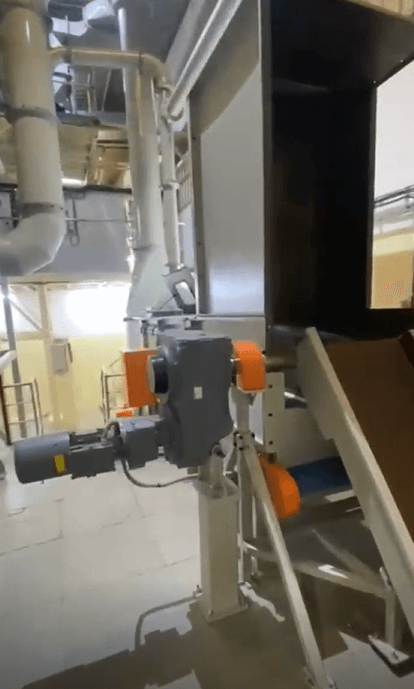

Challenge: Replace 500 kg/hr cleaning line within the same plant footprint

Solution: Install a 1500 kg/hr cleaning and conveying setup without expanding facility space

Outcome:

- Threefold increase in capacity

- Removal of plastic, metal, threads, glass, feathers, tobacco pouches

- Superior feed into downstream grinders and mixers

- Full compliance with export-grade cleanliness

This project exemplifies a scalable, automatic spice plant design—enabling major throughput gains without civil engineering changes.

MillNest spice grinding machines Energy‑Efficient

While spice ginding machines performance varies based on spice type and required output format, MillNest has engineered several core advantages:

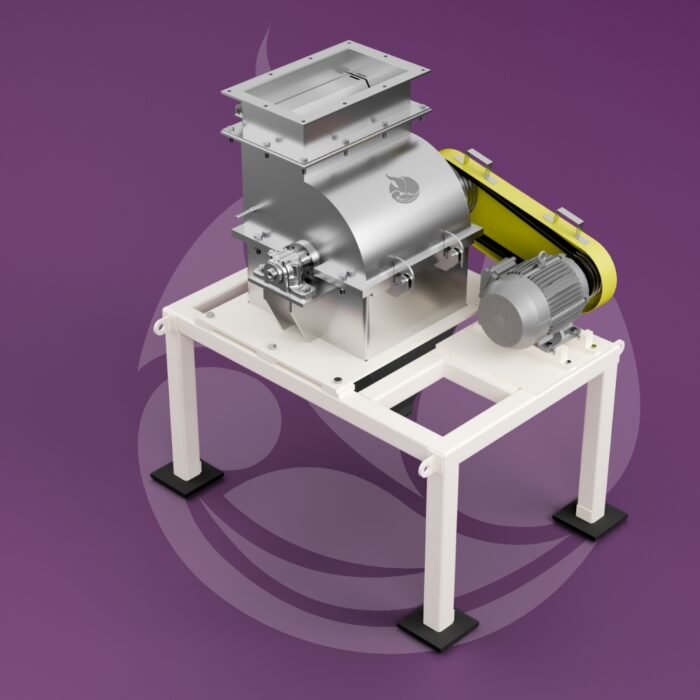

- Air Classifying Mill (MACM)—combines impact grinding with in-built classification to ensure precise particle size, eliminating overgrinding and reducing motor load

- Hammer Mill (MHAM)—delivers robust pulverization for coarser materials while maintaining lower energy draw

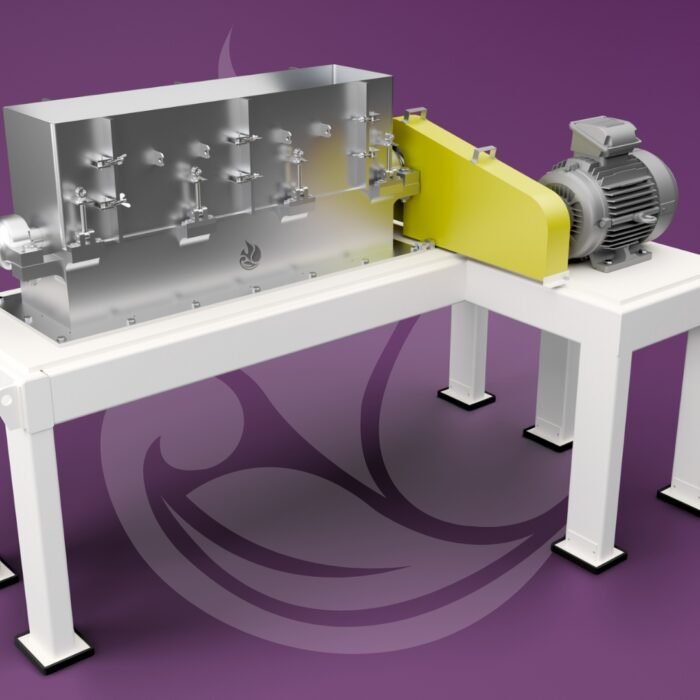

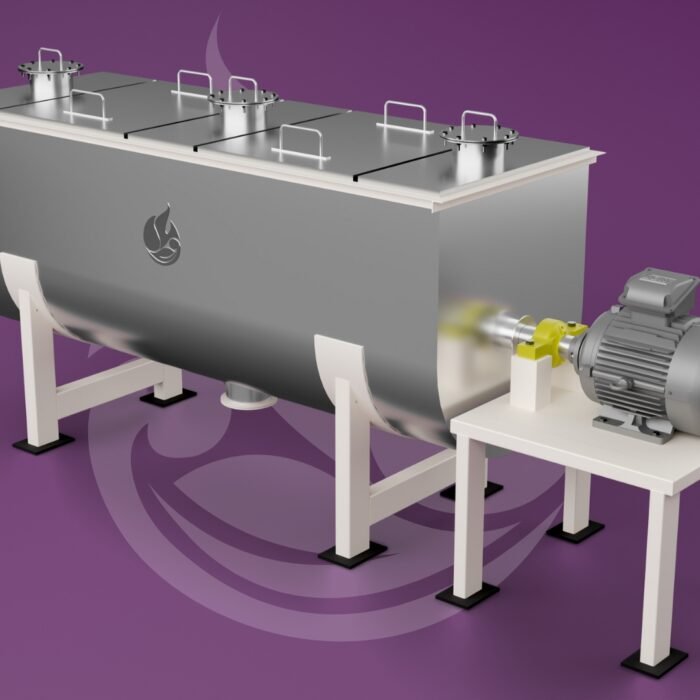

- Ribbon Blender (MRBL) and Paddle Blender (MPBL)—offer batch-level process control, faster cycle times, and CIP-compatible cleaning for minimal downtime.

These systems are designed to reduce energy input per kilogram, limit thermal damage to volatile spice oils, control dust leakage, and standardize outputs consistently across batches.

Plant-Level Outcomes: Efficiency Gains in Numbers

Across installations, MillNest systems deliver impressive aggregated results:

- Output improvement: from 1.5X to 3X within the same or smaller footprint

- Energy savings: up to 25% reduction in kWh per kg processed

- Cleaner process flow: closed-loop conveying systems reduce contamination and product loss

- Operational uptime: CIP-enabled mixers and modular design reduce changeover time by 30–40%

These outcomes with Spice Grinding Machines translate into measurable improvements in OEE (Overall Equipment Effectiveness) and tangible savings in power, labor, and yield.

Strategic Considerations with Spice Grinding Machines for Plant Heads & Boards

1. Timing the Upgrade

- When output is plateauing and product demand exceeds capacity

- When energy costs per batch rise sharply, squeezing margins

- When hygiene requirements evolve, particularly for export certifications

Upgrading is not just a cost—it’s a strategic move toward scaling with control and compliance.

2. Evaluating CapEx and OpEx Dynamics

- CapEx: Investing in machines like the MACM or MRBL will require higher upfront cost compared to legacy equivalents.

- OpEx savings: Spice Grinding Machines deliver reduced power consumption, fewer operators, less rework, and streamlined cleaning cycles—often resulting in rapid ROI within 12–18 months.

Aggregated savings over time justify the initial expenditure with quantifiable margin improvement.

3. Flexibility Through Modularity

- MillNest systems support modular layouts, allowing retrofit into existing facilities without major structural changes

- Multi-format machines (e.g. MACM capable of both powder and granule production) extend versatility

- Pre-configured mixing logic and feed control enable easy scale-up across spice varieties

This modularity means faster deployment, lower disruption, and easier future expansion.

4. Operational Control and Automation

- Integration with PLC or SCADA systems provides real-time monitoring of rotor speed, air flow, and batch logic

- Digital data capture enables traceability, critical for export documentation and quality systems

- Automated clean-in-place features ensure consistent hygiene without manual interventions

For boards, these features translate into less dependency on operators, better data control, and reduced compliance risk.

5. Risk Mitigation and Quality Consistency

- Size control ensures product uniformity—essential for downstream packing and brand consistency

- Thermal management prevents discoloration or oil loss in temperature-sensitive spices

- Closed systems reduce airborne loss and maintain sanitary conditions throughout processing

These controls minimize rejects, reduce QA variation, and enhance reliability in every batch.

For more detailed information on spice grinding processes and equipment, refer to this educational guide by KVIC

Conclusion: From Upgrade to Strategic Uplift

Grinding and mixing are now core levers of strategic improvement in spice manufacturing. With MillNest’s advanced spice grinding machines — MillNest Air Classifying Mill (MACM), MillNest Hammer Mill (MHAM), MillNest Ribbon Blender (MRBL), MillNest Paddle Blender (MPBL) — plants can achieve:

- Measurable energy savings and output gains

- Compact, hygienic, and integrated layouts

- Faster returns on investment through improved yield and reduced labor

- A consistent and scalable platform for industry-grade product manufacturing

Efficient production isn’t optional—it’s essential.

Contact MillNest for technical audits, custom designs, and turnkey solutions tailored to your plant’s output, space, and product mix.