Premium refurbished equipment gives food and spice processing businesses a smart way to balance capital expenditure with operational efficiency. As the cost of new machines continues to rise, manufacturers are turning to sustainable options that deliver faster ROI. With performance comparable to new systems at a fraction of the investment, premium refurbished equipment stands out as a practical and cost-effective choice.

The refurbished food processing machine market represents more than cost savings. It delivers strategic advantages including reduced lead times, proven reliability, and environmental sustainability that align with modern business priorities. Understanding how spice processing equipment refurbishment works can transform capital allocation strategies for processing facilities of all sizes.

What “Premium Refurbished Equipment” Means

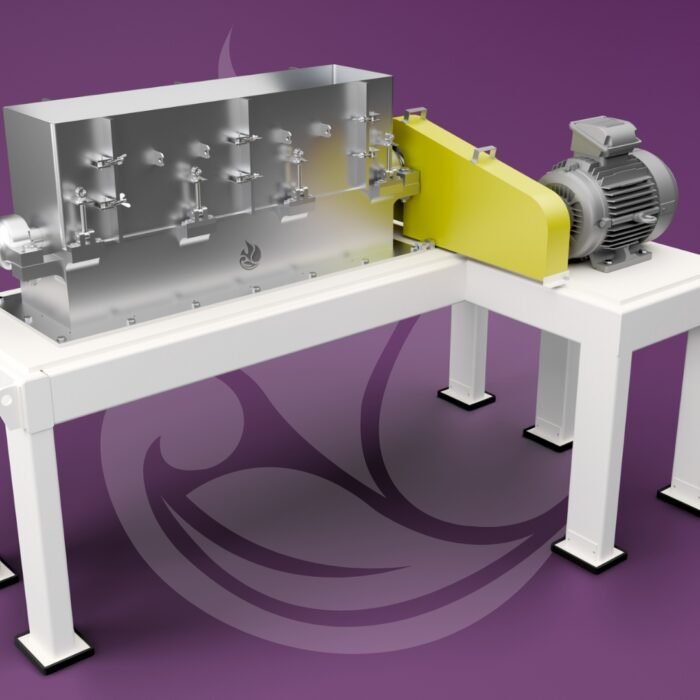

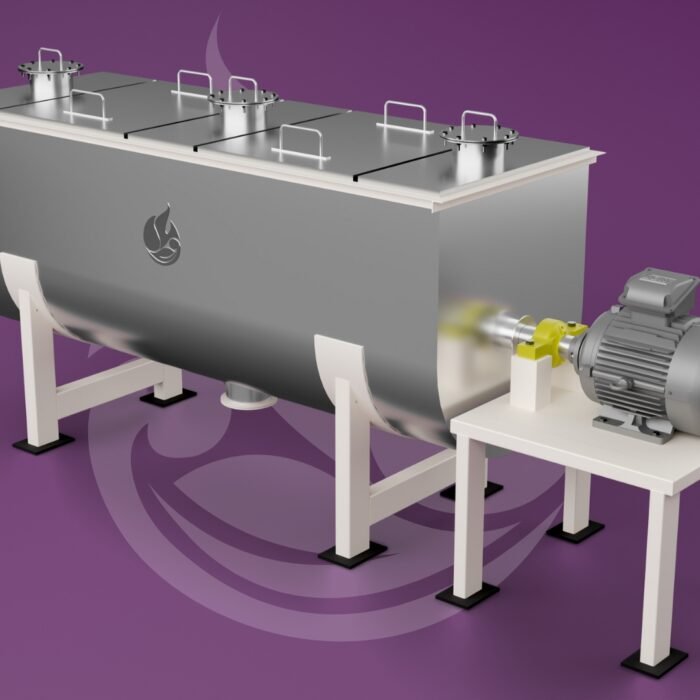

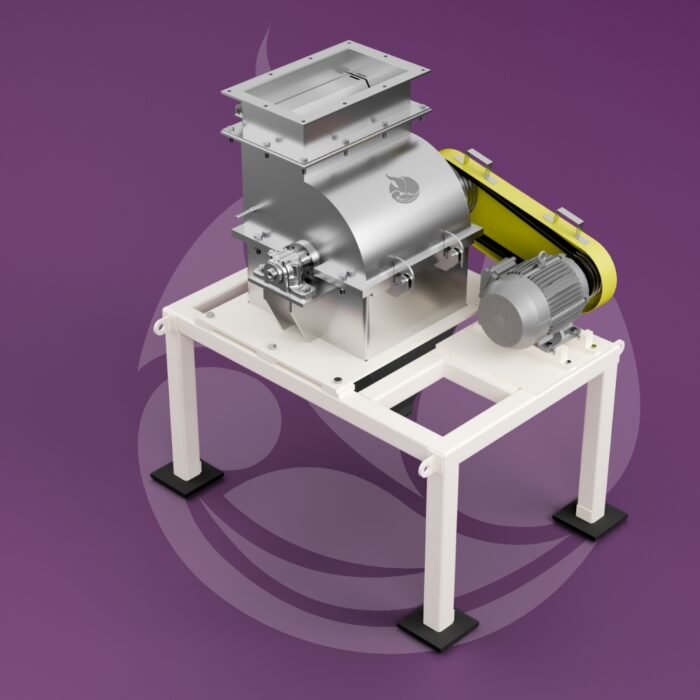

Premium refurbishment extends far beyond basic cleaning and cosmetic repairs. The process involves comprehensive machine disassembly, component evaluation, and systematic replacement of worn parts with original or equivalent specifications.

Comprehensive Refurbishment Process

- Complete Disassembly: Machines undergo complete teardown to the base frame, allowing thorough inspection of all components including motors, bearings, seals, and structural elements.

- Component Evaluation and Replacement: Critical wear components receive replacement with new parts meeting original manufacturer specifications. This includes processing chambers, screens, hammers, and drive systems.

- Systems Upgrade: Modern control systems, safety features, and energy-efficient components replace outdated elements, improving performance beyond original specifications.

- Quality Verification: Refurbished equipment undergoes rigorous testing protocols including performance validation, safety compliance verification, and operational reliability assessment.

Warranty and Support

- Comprehensive Warranty Coverage: Premium refurbished equipment includes warranty coverage comparable to new machines, typically spanning 12-24 months depending on equipment type and complexity.

- Technical Documentation: Complete operational manuals, maintenance schedules, and component specifications ensure proper operation and ongoing maintenance support.

- Post-Installation Support: Ongoing technical support, parts availability, and service coverage provide the same level of support as new equipment purchases.

Performance & Reliability

Modern refurbishment techniques deliver performance standards that match or exceed original equipment specifications. The systematic approach ensures reliability that supports continuous production requirements.

Engineering Standards

- Precision Restoration: Critical tolerances and specifications receive restoration to original manufacturer standards through precision machining and component replacement.

- Performance Validation: Testing protocols verify that premium refurbished equipment meets original performance parameters including throughput capacity, particle size distribution, and energy consumption.

- Safety Compliance: Updated safety systems ensure compliance with current food processing regulations including FSSAI, FDA, and international safety standards.

Reliability Metrics

Manufacturing industry data demonstrates that properly refurbished equipment achieves reliability rates comparable to new machines. The comprehensive refurbishment process addresses wear patterns and failure points, often resulting in improved long-term reliability.

- Component Longevity: New critical components installed during refurbishment provide fresh operational life equivalent to new equipment.

- Predictable Maintenance: Known operational history combined with new components enables predictable maintenance scheduling and reduced unexpected downtime.

Cost Benefits & ROI

The financial advantages of premium refurbished equipment extend beyond initial purchase price savings to include reduced lead times, lower total cost of ownership, and accelerated return on investment.

Purchase Price Advantages

Premium Refurbished equipment typically costs 30 to 70% less than brand-new models, providing significant capital expenditure reductions for expanding businesses and startups. This cost differential allows processors to invest in higher-capacity or more sophisticated equipment within existing budget constraints.

- Capital Allocation Optimization: The substantial savings enable businesses to allocate capital across multiple equipment upgrades or invest in complementary systems such as packaging, quality control, or automation.

- Budget Flexibility: Lower initial investment provides financial flexibility to address unexpected operational needs or market opportunities without compromising equipment quality.

Lead Time Benefits

- Immediate Availability: Premium Refurbished equipment availability typically ranges from 6-8 weeks compared to 12+ months for new equipment orders, enabling rapid production expansion or replacement of failed equipment.

- Production Continuity: Shorter lead times minimize production disruption during equipment upgrades or emergency replacements, maintaining customer delivery commitments.

- Market Responsiveness: Quick equipment deployment enables rapid response to market opportunities or seasonal demand fluctuations common in spice processing operations.

Total Cost of Ownership

- Reduced Depreciation: Lower initial investment reduces depreciation impact on financial statements while providing equivalent operational capabilities.

- Energy Efficiency: Modern control systems and energy-efficient components installed during refurbishment often improve energy performance compared to original specifications.

- Maintenance Cost Predictability: New critical components provide predictable maintenance schedules and reduced unexpected repair costs during early operational years.

Energy, Sustainability & Environmental Impact

Sustainable equipment for spice industry applications provides measurable environmental benefits while reducing operational costs through improved energy efficiency.

Energy Performance Improvements

Manufacturing retrofits demonstrate significant energy consumption reductions. EMAG’s retrofit examples show comprehensive machine modernization where old hydraulic systems are replaced with servo-electric drives, delivering improved accuracy and energy efficiency. While this data comes from machining equipment, analogous improvements occur in food processing equipment retrofits where modern motor systems and control technologies replace older, less efficient components.

- Motor Efficiency Upgrades: Modern high-efficiency motors (IE3/IE4 class) replace older standard motors, reducing energy consumption by 15-25% compared to original installations.

- Control System Optimization: Advanced control systems optimize operational parameters, reducing energy waste during startup, idle periods, and load variations.

- Variable Frequency Drives: VFD installations enable precise speed control, matching power consumption to processing requirements and reducing overall energy usage.

Environmental Sustainability

- Resource Conservation: Equipment refurbishment extends machine life cycles, reducing demand for new manufacturing resources including steel, aluminum, and rare earth elements used in motors and controls.

- Waste Reduction: Refurbishment prevents equipment disposal in landfills while maximizing utility from existing manufacturing investments.

- Carbon Footprint Reduction: Avoiding new equipment manufacturing reduces embedded carbon footprint while transportation emissions remain minimal due to local or regional refurbishment facilities.

Circular Economy Benefits

- Material Recovery: Component reuse and material recovery during refurbishment supports circular economy principles by maximizing value from existing resources.

- Extended Equipment Life: Proper refurbishment can extend equipment operational life by 10-15 years, multiplying the return on original manufacturing investments.

- Supply Chain Efficiency: Local refurbishment reduces international shipping requirements and associated environmental impacts.

Key Considerations & Risk Mitigation

Successful refurbished food processing machine procurement requires careful evaluation of refurbishment quality, compliance standards, and ongoing support capabilities.

Hygiene & Safety Standards

- Food Safety Compliance: Refurbished equipment must meet current food safety regulations including FSSAI guidelines for spice processing facilities. This includes material specifications, surface finish requirements, and cleanability standards.

- Sanitary Design Verification: Critical food contact surfaces require verification of proper materials (typically SS 304/316), surface finish specifications, and elimination of contamination harboring points.

- Documentation Requirements: Complete refurbishment documentation ensures traceability for regulatory compliance and quality system requirements.

Quality Assurance

- Inspection Protocols: Comprehensive inspection procedures verify that refurbishment meets established quality standards including dimensional accuracy, surface condition, and operational performance.

- Testing and Validation: Performance testing validates that premium refurbished equipment meets original specifications for throughput, particle size control, and operational parameters.

- Certification Requirements: Equipment certification ensures compliance with relevant safety and performance standards applicable to food processing operations.

Warranty & Support Considerations

- Comprehensive Coverage: Warranty terms should cover both mechanical components and electrical systems with clear definitions of coverage scope and duration.

- Parts Availability: Long-term parts availability ensures ongoing maintenance support throughout equipment operational life.

- Technical Support: Access to technical expertise for installation, commissioning, and ongoing operational support proves essential for successful equipment integration.

Risk Mitigation Strategies

- Supplier Qualification: Thorough evaluation of refurbishment supplier capabilities, quality systems, and track record reduces procurement risks.

- Performance Guarantees: Written performance guarantees provide recourse if refurbished equipment fails to meet specified operational parameters.

- Inspection Rights: Rights to inspect equipment during refurbishment process enable early identification and resolution of potential issues.

Why Choose MillNest Originals

MillNest brings decades of spice processing equipment expertise to the refurbishment process, ensuring that cost-effective food processing solutions meet the demanding requirements of modern spice processing operations.

Engineering Excellence

- Design Knowledge: Deep understanding of MillNest equipment design enables comprehensive refurbishment that addresses known wear patterns and potential improvement opportunities.

- Manufacturing Precision: Access to original manufacturing specifications, tolerances, and assembly procedures ensures refurbishment meets original quality standards.

- Continuous Improvement: Refurbishment process incorporates design improvements and lessons learned from ongoing equipment development programs.

Quality Standards

- Manufacturing Heritage: MillNest’s reputation for precision manufacturing extends to refurbishment operations, ensuring consistent quality across all restored equipment.

- Component Sourcing: Access to original parts and approved equivalents ensures compatibility and performance consistency.

- Testing Capabilities: Comprehensive testing facilities validate equipment performance before delivery, ensuring reliability and operational readiness.

Service Support

- Technical Expertise: Experienced service technicians provide installation, commissioning, and ongoing maintenance support for premium refurbished equipment.

- Training Programs: Operator training ensures proper equipment utilization and maintenance, maximizing equipment life and performance.

- Parts and Service Network: Established parts inventory and service network provides ongoing support throughout equipment operational life.

Customization Capabilities

- Application-Specific Modifications: Refurbishment process can incorporate modifications for specific spice processing requirements including specialized screens, cooling systems, or automation integration.

- Capacity Optimization: Equipment modifications can optimize throughput capacity for specific product characteristics or production volume requirements.

- Integration Support: Technical support for integration with existing production lines ensures seamless operation within established processing systems.

Conclusion

Premium refurbished equipment represents a strategic investment that delivers new-machine performance while providing substantial cost advantages and sustainability benefits. The combination of reduced capital requirements, shorter lead times, and proven reliability makes refurbished food processing machine procurement an intelligent choice for spice processing businesses.

Spice processing equipment refurbishment through MillNest Originals provides access to precision-engineered equipment at reduced investment levels while maintaining the quality standards that define successful processing operations. The comprehensive refurbishment process, backed by engineering expertise and ongoing support, ensures operational success and long-term value.

Ready to explore how premium refurbished equipment can optimize your processing operations? Contact MillNest today to assess your plant’s opportunities for cost-effective food processing solutions through our refurbishment program. Request a comprehensive evaluation of your spice processing line to identify equipment upgrade opportunities that deliver immediate ROI while supporting sustainable business growth.